Having come into existence from the earliest of human civilizations, tunnels have long been a part of mankind. However, things have changed drastically, when it comes to the whole lifecycle of a bridge, right from its very ideation to long-term maintenance.

Importance of a Tunnel Monitoring System

Before diving into the numerous types of tunnel monitoring sensors, it’s key to know why they’re significant. Ultimately, all these instruments are implemented to create a complete monitoring system to analyze the tunnel’s behavior over time. Moreover, it also helps to verify the stability of the tunnel, understand if its design is credible or not, and assess the sequence and intensity of the various operations its construction will involve.

All in all, tunnel monitoring reflects its significance in three main areas: –

- During a tunnel’s design, instrumentation is installed to gather data on existing ground conditions. Here, the monitoring sensors are usually installed in the boreholes and exploratory tunnels available on the surface. Monitoring tunnels to collect this data is a key part of optimizing the tunnel’s design and making it as safe and effective as possible.

- During the construction stage. This is probably the most important area where tunnel monitoring is required. The various sensors installed to capture and transmit data indicate if the initial design assumptions were correct, and how the design is performing in reality. This is extremely vital as it helps to fix design loopholes beforehand, saving both time and money.

The tunnel monitoring instrumentation installed on the surface provides data on the subsurface and surface conditions. These sensors are also installed on structures on the surface that fall within the construction’s vicinity, and hence, are likely to be affected.

- Monitoring tunnels for the long run is also where these sensors come into play. These continue to monitor the tunnel during its operational stages, maintaining and ensuring its stability, and safety, and determining any natural calamity’s effect on the structural integrity. This also streamlines the maintenance schedules and contributes to the tunnel’s longevity.

| Also Read Emerging Technologies in Tunnel Instrumentation and Monitoring |

The Various Tunnel Monitoring Sensors Involved

Now that we’ve covered the role played by tunnel monitoring, it’s time to take a look at the instruments that aid this, i.e. the sensors. At Encardio Rite, we offer a wide range of tunnel monitoring instrumentation, applicable to various use cases. Here’s the complete list: –

1. In-place inclinometers:

Our vertical in-place inclinometers, model EAN-52M, consist of various biaxial probes and are mounted vertically with SDI-12 output, in a borehole. Using a daisy chain manner, these sensors are connected via a single output cable to consistently monitor sub-surface lateral movements.

2. Piezometers:

Piezometers are also one of the most commonly used sensors for monitoring tunnels. The Encardio Rite EPP-30V model, a vibrating wire piezometer, is used along with the ESVI-10VB SDI-12 or ESVI-01-01 interface box to monitor pore pressure variations.

| Also Read: Piezometers: Types, Functions, & How It Works? |

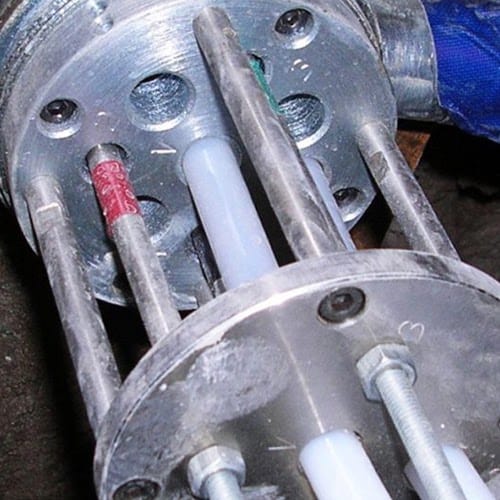

3. Extensometers:

Extensometers, namely our EDS-70V multiple point borehole extensometers (vibrating wire type), with an ESVI-01-04 SDI-12 interface box, are installed for tunnel monitoring. These extensometers are used to monitor lateral movements and sub-surface settlements at specific depths.

4. Tilt meters:

Biaxial tiltmeters are usually installed in multiple locations on the various structures within the influence zone while a tunnel is constructed. Our model EAN-93M-B or EAN-92M-B are examples of such tiltmeters used to record tilt changes in the structures.

5. Crack meters:

Vibrating wire crack meters, like our EDJ-40V, help to monitor the opening or displacement of existing cracks in the structures situated within the influence zone. These are installed with interface boxes, such as Encardio Rite’s model ESVI-01-01 SDI-12.

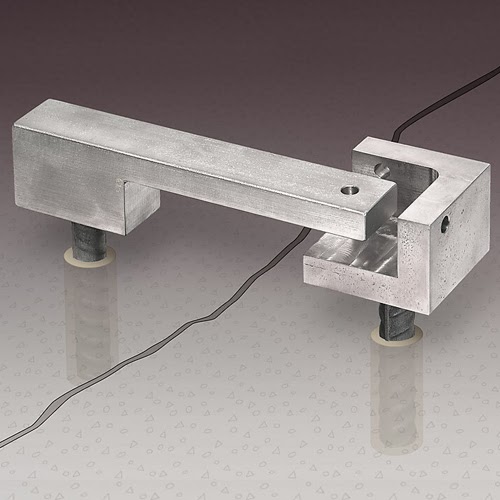

6. Load cells:

When it comes to tunnel monitoring instrumentation, load cells are quite commonly used as well. Center hole load cells (resistive strain gauge type), such as our ELC-30SH/30S model, are installed along with interface boxes to monitor tension in rock bolts and anchors. On the other hand, strut load cells are mounted to monitor the stress on struts, support beams, piles, etc.

7. Pressure cells:

Vibrating wire pressure cells are mainly used in tunnel monitoring. There are two types applicable for this – the shotcrete or concrete pressure cells used to monitor tangential and radial stress in concrete pre-cast segments or shotcrete linings, during construction. At Encardio Rite, our models ESC-30V (shotcrete) and EPS-30V (concrete) are used for this purpose.

8. Strain gauges:

Vibrating wire strain gauges are yet another sensor used widely for tunnel monitoring systems. These allow monitoring of any sort of strain in the concrete pre-cast segments and tunnel linings. A great example is our model EDS-20V-AW or EDS-20V-E.

9. Digital inclinometers:

Digital inclinometer systems can also be used for tunnel monitoring. These usually include a digital tilt-sensing probe. This traversing sensor is attached to a unit comprising a winding reel to hold the cable, along with a wireless Bluetooth relay unit. This unit then transmits the probe’s data to the readout unit.

To Sum It Up

As you can see now, there is a diverse range of tunnel monitoring sensors that are utilized to devise an ideal monitoring plan. At Encardio Rite, we specialize in providing such instrumentation to ensure long-term tunnel monitoring safety. Moreover, our sensors come with a proven track record for unrivaled performance and reliability under the harshest of conditions.