Piezometers are the geotechnical sensors that are used to measure pore water pressure (piezometric level) in the ground. It is designed to measure pore water pressure in the soil, earth/rock fills, foundations, and concrete structures.

Considered one of the most important geotechnical monitoring instruments, it’s interesting to study as well. Let’s discuss more about piezometers, their types, working principles, applications, and functions in detail.

What is a Piezometer?

Piezometers or pore pressure meters are pressure transducers that are installed beneath the ground to measure the sub-surface piezometric level within groundwater level, soil, or rock. Now that you are well-versed with the piezometer definition, let’s move forward to understanding its usage in the geotechnical domain.

Proper evaluation of pore pressure helps in monitoring the behavior after construction and indicates potentially dangerous conditions that may adversely affect the stability of the structure, its foundation, and its appurtenant.

It also provides basic data for design improvement that will promote safer and more economical design and construction. The Casagrande piezometer is considered the simplest form of piezometer. It consists of a Casagrande tip connected to the lengths of the extension pipe. The water level inside the pipe is measured using the diameter.

However, the vibrating wire piezometer is most commonly used because of accurate results and higher reliability. I am sure you understand what a Piezometer is, let’s take a look at the application of the sensor.

Why is a piezometer used?

The use of a piezometer has the following purposes:

- To study the effect of water in the pores of soil or rock is to reduce load bearing capacity of soil or rock. The effect is more pronounced with higher pore water pressure leading eventually in some cases to total failure of load bearing capacity of the soil.

- A piezometer is extensively used in Groundwater Monitoring to determine the level and flow pattern of groundwater.

- To determine the flow pattern of water in earth/rock fill, concrete dams, and their foundations.

- To delineate the phreatic line.

Read more: Vibrating Wire Piezometer – Types and Operating Principle

What are the types of piezometers?

Piezometers or pore pressure meters are available in different shapes and sizes.

Here are the different piezometer types that are currently being used to measure the pore pressure inside boreholes and beneath the earth’s surface. Let’s take a look at the piezometer principle and more!

1. Casagrande or Open Standpipe Piezometers

One of the simplest instruments to measure the piezometric level in the ground is an Open Standpipe Piezometer or Casagrande. It is a plastic pipe, with a small diameter (up to 20mm) and a porous section at the bottom.

This pipe is installed inside a borehole while placing the porous section at the bottom where the piezometric level is to be measured. The annulus between the porous filter and the borehole has sand in it, sealed from both sides using bentonite, and the rest of the borehole is filled with cement mortar.

The groundwater pressure pushes the water into the standpipe until the level of water inside the standpipe (h) is equal to the piezometric level (pore water pressure) in the ground at the elevation of the porous filter. That is how the piezometer water level is used and monitored.

2. Electric Piezometers

The next types of piezometers include electric piezometers that consist of a deflecting diaphragm and a porous filter divided by a small reservoir of water. A vibrating wire or a strain gauge is used to calculate the deflections of the diaphragm. The piezometer-measured results are then converted to an equivalent pressure using proper calibration.

The next procedure is exactly similar to the open standpipe piezometers. The electric piezometer is inserted into a borehole while the annulus between the porous filter and the borehole is filled with cement/bentonite grout.

Water from the ground pushes itself due to buoyant force into the reservoir and causes deflections in the diaphragm until the pressure inside the reservoir is the same as the pore water pressure (piezometric level) in the ground at the elevation of the porous filter.

If an electric piezometer is installed above the current groundwater table, the pore pressure in the soil is negative and the water in the piezometer will be drawn out of the reservoir. If this happens, the piezometer will be filled with air, leading to its dysfunction.

3. Hydraulic Piezometers

The third type of piezometer is the hydraulic piezometer which consists of a porous filter containing a reservoir of water, separated from a pressure gauge via resilient and water-filled tubes.

These tubes circulate water through the system to remove air and ensure that the reservoir remains filled with water.

The piezometer measures overall hydraulic pressure from which pore pressure can be calculated.

4. Pneumatic Piezometers

The next type of piezometer is the pneumatic piezometer which is operated by gas pressure. Application of Piezometer is found in a borehole, fills, or in a large diameter standpipe. The readings are then calculated with a pneumatic indicator.

5. Vibrating Wire Piezometers

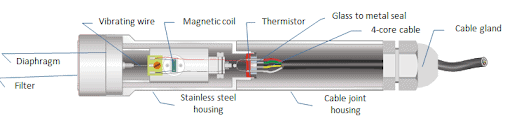

The Vibrating Wire Piezometers measure the pore water pressure in fully or partially saturated soil and rock. A vibrating wire piezometer basically consists of:

- A sensitive stainless steel diaphragm

- A magnetic, high tensile strength stretched wire, one end of which is anchored and the other end is fixed to a diaphragm.

- Ceramic low air filter (brass high air entry filters are also used depending on site requirements)

- Thermistor for temperature readings

- Glass to metal seal with four terminals for cable connection

- Stainless steel body with resistance to rusting or corrosion against several kinds of dissolved impurities found in water under field conditions. For saline water application, a special sensor with additional protection is provided

What is the pore water pressure/Piezometric Level?

The pore water pressure/Piezometric Level is the pressure experienced by water contained in pores of earth materials or concrete structures.

In any instrumentation scheme for geotechnical or geo-structural study associated with large civil engineering structures like tall buildings, dams, underground tunnels etc., measurement of pore water pressure (also known as the piezometric level) plays an important part. This is where the use of a piezometer comes into play.

How does a piezometer work?

The vibrating wire piezometer basically consists of a magnetic, high tensile strength stretched wire, one end of which is anchored and the other end fixed to a diaphragm that deflects in some proportion to applied pressure.

The piezometer function is dependent on the pressure changes. Any change in pressure deflects the diaphragm proportionally and this, in turn, affects the tension in the stretched wire. Thus any change in pore pressure directly affects the tension in the wire.

The wire is plucked by a coil magnet. Proportionate to the tension in the wire, it resonates at a frequency ‘f’, which can be determined as follows:

f = {[σg/ρ] ^1/2}/ 2l Hz

Where σ = tension of the wire

g = gravitational constant

ρ = density of the wire

l = length of wire

The resonant frequency, with which the wire vibrates, induces an alternating current in the coil magnet. This explains the piezometer equation or the formula.

The pore pressure is proportional to the square of the frequency and the Encardio Rite model EDI-51V readout logger (data logger) is able to display this directly in engineering units.

Piezometer Types – Encardio Rite’s Models

1. Model EPP-10SP/ Open Standpipe Piezometer or Casagrande

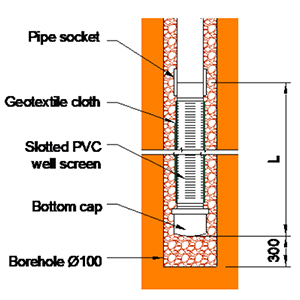

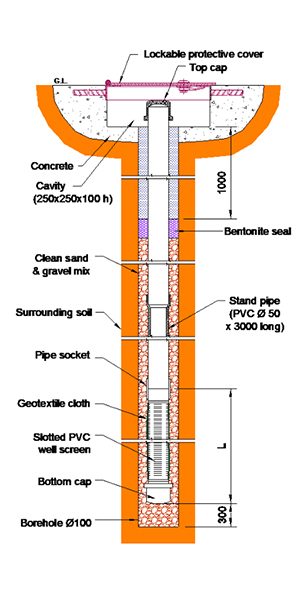

Observation wells are vertical pipes with a slotted section at the bottom typically installed in boreholes with a seal at the surface to prevent surface water from entering the borehole.

The depth of the water level is measured by lowering the water level measurement probe into the pipe. The Model EPP-10 SP standpipe is used for measuring groundwater level and its variation with time.

The Encardio Rite model EPP-10SP standpipe piezometer consists of a pipe that is sealed along its entire length and installed in a borehole such that it must be open to water flow at the bottom and open to the atmosphere at the top. The intake is a slotted pipe covered with geotextile material. The Piezometer instrument is essential for borehole monitoring.

Construction of Open Standpipe Piezometer

The standpipe consists of a series of PVC standpipes, 50 mm o.d., 44.5 i.d., and 3m length with an inbuilt socket for jointing.

The intake point of the standpipe consists of a PVC slotted pipe, 1 m long, 50 mm o.d., covered with geotextile. The bottom end of the slotted pipe is plugged with a suitable PVC cap.

Open Standpipe Piezometer Installation

The piezometer installation detail is as follows.

The standpipe is set in a borehole, which is drilled into the soil/foundation to a pre-determined depth to intercept groundwater. The slotted pipe is connected by a socket to the same-diameter plastic standpipes extending to the surface.

The borehole is filled with pea-gravel. The top of the borehole is sealed with a cement bentonite plug.

Groundwater seeps into the standpipe through the slotted end and attains a level equal to groundwater. This level is determined by an electrical-sounding device model EPP-10/6 lowered from the surface.

A plate-hinged cover with a locking arrangement is available for mounting at the top of the standpipe.

The locking arrangement has a universal key and a dust protection cap

2. EPP-10/6 Water Level Indicator

The Model EPP-10/6 water level indicator is designed to measure the elevation of groundwater in boreholes, standpipes, and wells. It is robust, lightweight, and convenient to use. The water level sounder probe is lowered from the surface with the help of the connecting flat cable for taking observations.

The length of the cable is commensurate with the depth up to which the observation is required to be made. The unit is battery operated complete with an on-off switch, buzzer, LED for power on and signal, flat cable connected to a probe, winding reel, and carrying handle. The piezometer for groundwater is explained below.

The probe gives sound and light signals when water in the borehole/well makes contact with the tip. The moisture-resistant electronics and standard 9 V PP-3 size batteries are housed in a hub on the cable reel. The hub can be easily removed to replace the battery or check the electronics without disassembling the entire cable reel.

3. Model EPP-30V/ Electron Beam Welded Heavy-Duty VW Piezometer

In the Model EPP-30V electron beam welded heavy-duty vibrating wire piezometer, the vibrating wire and coil magnet assembly are enclosed in a stainless steel body which is an electron beam welded to the diaphragm.

This results in a vacuum of around 1/1000 Torr inside the sensor making it immune to the effect of any ingress of water and other corrosive materials that may be present in the water. As the piezometer is of stainless steel construction, it is not affected by normal chemical corrosion at the locations in which it is used.

Figure 1: Model EPP-30V electron beam welded piezometer

A low air entry value ceramic flat filter with a thickness of 3 mm and a grain size of 40-60 microns is normally provided.

The water oozes through internal pores or seams in rock formations of dam foundations, mass concrete of structures, foundation soil of structures, reclaimed land soil, etc. percolates through the filter to pressurize the diaphragm.

A locking nut holds the filter in position. For filling up the cavity behind the filter with de-aired water before installation and for saturating the filter with water, a bent nose plier is used to remove and again assemble the locking nut.

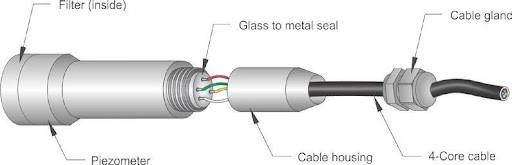

Depending upon the application filters with different porosity and air entry values are available. The leads from the coil magnet are terminated on the glass-to-metal seal which is integrally welded to the stainless steel body of the piezometer.

The two pins marked red and black are connected to the coil magnet. The other two pins are connected to a thermistor. A cable joint housing and a cable gland are provided for the connection. Normally, the piezometer is supplied without any cable attached to it. Cable jointing with the required length of appropriate cable can be easily done at the site.

EPP-30V/1 Stainless steel VW sensor

Another piezometer type includes the Model EPP-30V. The vibrating wire and coil magnet assembly is enclosed in a corrosion-resistant stainless steel body which is an electron beam welded to the diaphragm.

EPP-30V/2 Metallic/ Ceramic filter

A low air entry value ceramic filter of 40-micron porosity is provided. A locking nut holds the filter in position through a suitable ‘O’ ring. Other types of filters are available as an option.

EPP-30V/3 Cable joint housing

Leads from the coil magnet are terminated on a glass-to-metal seal which is an electron beam welded to the stainless steel body of the pore pressure meter. Two pins marked red and black are connected to the coil magnet. A cable joint housing and a suitable cable gland are provided for the cable connection.

4. Model EPP-40V Vibrating Slim Wire Piezometer

The Encardio Rite Model EPP-40V piezometer is well known for its long-term stability. The piezometer working is achieved by:

- Aging pressure and thermal cycling

- The unique method of wire clamping

- By generating a vacuum of around 1/1000 Torr inside the sensor by electron beam welding. This results in the effect of oxidation, moisture, environmental conditions, and any ingress of water being completely eliminated.

The vibrating wire pressure-sensing capsule is sealed under a high vacuum. The capsule and coil magnet assembly is housed in a stainless steel body.

Leads from the coil magnet are terminated on the glass to a metal seal which is an electron beam welded to the stainless steel body of the piezometer. A cable joint housing and a suitable cable gland are provided for the cable connection. The sensor can also be supplied with the required length of cable attached.

The pressure sensor is individually temperature compensated making the requirement of a thermistor for temperature correction redundant. However, a thermistor is provided for monitoring temperature.

5. Model EPP-60V Vibrating Wire Low-Pressure Piezometer

The Encardio Rite Model EPP-60V vibrating wire low-range piezometer is specially designed to measure low water pressure and water levels in boreholes.

It provides significant quantitative data on groundwater level, groundwater pressure & its variations with time.

Proper evaluation of water level helps in monitoring the behavior after construction & indicates potentially dangerous conditions that may adversely affect the stability of the structure and its foundation.

It also provides basic data for design improvement that will promote safer and more economical design and construction.

Two variants are available:

- Gauge pressure sensor with vented cable, used for applications in which maximum hydrostatic head (height of water level above piezometer location) is less than 7 m over the sensor diaphragm.

- Absolute pressure sensor with 20 m range, which is electron beam welded and comes with non-vented cable.

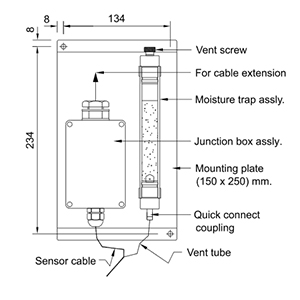

Gauge pressure sensor (with vented cable)

The capsule and coil magnet assembly is housed in a stainless steel body with two small openings provided on the glass-to-metal seal.

The sensor with a range of 7 m is supplied with the required length of the vented tube cable attached.

This shielded cable has two vent tubes running through it which connect the inside of the sensor to the outside atmosphere, thus ensuring that the sensor reading is unaffected by any change in barometric pressure.

The open end of the vent tubes in the cable terminates into a moisture trap assembly consisting of a terminal box and desiccant chamber at the top of the borehole thus preventing any moisture from migrating into the vent tube or the sensor.

Absolute pressure sensor (with EBW)

The vibrating wire pressure-sensing capsule is sealed under a high vacuum. The capsule and coil magnet assembly is housed in a stainless steel body. Leads from the coil magnet are terminated on the glass to a metal seal which is an electron beam welded to the stainless steel body of the piezometer.

A cable joint housing and a suitable cable gland are provided for the cable connection. The sensor can also be supplied with the required length of cable attached. Model EPP-60V piezometers are individually temperature-compensated making the requirement of a thermistor for temperature correction redundant.

However, a thermistor is provided for monitoring temperature.

6. Model EPU-20V/EPU-20G Vibrating Wire Uplift Pressure System

The uplift pressure measurement system is used for monitoring the uplift pressure of water in the foundation of dams and concrete structures and the stability of foundations of embankments in dams, tunnels, and other underground works.

It provides significant quantitative data on the magnitude and distribution of the uplift pressure of water and its variations with time. It also provides the pattern of seepage, zones of potential piping, and the effectiveness of seepage control measures undertaken.

The uplift pressure measuring device consists of a perforated/non-perforated pipe of 50 mm diameter of adequate strength. The pipe is inserted in a drilled hole in the foundation from the instrumentation gallery to the required depth. To the other end of the pipe in the gallery is connected the uplift pressure meter or a Bourdon pressure gauge.

7. Model EPU-20V Uplift Pressure Meter

Model EPU-20V sensor incorporates the latest vibrating wire technology to provide a remote digital readout of fluid and/or water pressure in standpipes, boreholes, and embankments.

It is similar to the model EPP-30V piezometer except for some changes in piezometer specification. Instead of the special filter, a 25 mm BSP adapter is provided for the pipe connection. The water oozes through internal pores or seams in rock formations of dam foundations, mass concrete /foundation soil of structures, reclaimed land soil, etc. percolates upward through the pipe to the sensor.

8. Model EPP-50V/ Vibrating Wire Push-In Piezometer

The Encardio Rite Model EPP-50V push-in vibrating wire piezometer is specially designed to measure pore water pressure in soft soil, clays, and landfills in earth-fill dam foundations & structures.

Long-term stability is ensured in the model EPP-50V Encardio Rite pore pressure meter by:

- Pressure and thermal cycling

- The unique method of wire clamping

- By generating a vacuum of around 1/1000 Torr inside the sensor by electron beam welding. This results in the effect of oxidation, moisture, environmental conditions, and any ingress of water being eliminated.

The vibrating wire pressure-sensing capsule is sealed under a high vacuum. The capsule and coil magnet assembly is housed in a stainless steel body. The Model EPP-50V vibrating wire push-in piezometer has a pointed cone at one end and drill rod threads (EW drill or M28) at the other end.

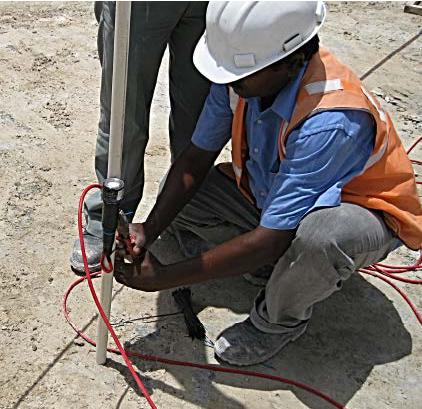

When threaded into a drill rod, the piezometer can be pushed into soft soil directly. The cable attached to the piezometer is passed through the drill rod. The piezometer must be monitored to ensure that the pressure created during vibrating wire piezometer installation does not exceed the maximum rated pressure.

The piezometer Model EPP-50V is supplied with the required length of cable attached. The pore pressure meter is individually temperature-compensated making the requirement of a thermistor for temperature correction redundant. However, a thermistor is provided for monitoring temperature. This is how the piezometer works!

EPP-50V/1 Stainless steel sensor

The vibrating wire and coil magnet assembly is enclosed in a corrosion-resistant stainless steel body which is an electron beam welded to the diaphragm.

EPP-50V/2 Metallic filter

A low air entry value stainless steel filter of 40-micron porosity is provided. High-air entry filters are also available as an option.

The filter can be taken out for saturation. A locking nut holds the filter in position through a suitable ‘O’ ring.

Read More: What Are The Different Types Of Piezometers?

FAQs:

Q1. How to Install Piezometer in Borehole/Foundation?

Ans: Installation of a piezometer in a borehole is done with a fully grouted method. Installing multiple piezometers in a borehole using the traditional method, which involves the placement of sand pockets surrounding the piezometers, bentonite seals, and grout columns to separate piezometers at different levels, is slow and complex. It also poses a risk of unintended communication between piezometers. The fully grouted method is quick and easy and results in excellent zone isolation.

Vibrating wire piezometers are the electrical piezometers of choice to implement this method as these require very little volume of water to register a change in pore water pressure, thus resulting in fast response time.

Figure 2: Fully Grouted Installation

Q2. How to Install Piezometer in Earth and Rock Fill Dam?

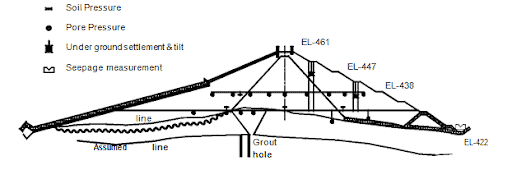

Ans: In an earth and rock fill dam, a number of piezometers and maybe other sensors are installed at selected elevations at different cross-sections, as shown in the figure below:

Q3. How to Install Piezometer in Concrete Dam?

Ans: As access galleries are available in concrete dams, the cable from the sensors is first routed to the gallery. These cables may be terminated in junction boxes inside the gallery. The data from the various sensors can then be taken or logged from the junction boxes with the help of a readout unit or data logger.

Alternatively, if required, the signals from the junction boxes may be carried through multicore cables to any observation room outside the dam structure.

Q4. How to Install Piezometer in Soft Soil?

Ans: For installation in soft soils, the Encardio rite model EPP-50V push-in piezometer is recommended. It does not require any elaborate grout sealing below and above the piezometer as required for other piezometer models. The EPP-50V has a hard conical tip that allows the piezometer to be pushed into the required depth from the ground surface or the base of a drilled borehole.

Can a vibrating wire piezometer measure negative pore water pressure?

A vibrating wire piezometer is the only device that can measure negative pore pressures because it indicates absolute pressures. Encardio Rite’s vibrating wire piezometers are fitted with high air entry porous filters that remove the air inside the piezometer so that the readings are accurate.

Q5. Where is the Piezometer used?

Ans: A piezometer is used for the following purposes:

- Construction control, stability investigation, and monitoring of earth dams, embankments, foundations, shallow underground works, and surface excavations.

- Uplift and pore pressure gradients in foundations, embankments, abutments, and fills.

- Hydrological investigation, groundwater pressure study, and water supply operations.

- Pore pressure studies in relation to waste and environmental applications.

- Monitoring of pore pressure for soil improvement & stability and for slope stability

- Reclamation of land in high population density areas in coastal regions for building highways, multi-storied structures, port trusts, or recreational facilities.

This requires extensive instrumentation for the measurement of horizontal displacement, vertical movement, and pore pressure.

- In coastal areas, it is necessary to determine and implement a strategy to overcome salinity problems and to increase community understanding and involvement in finding and implementing a solution.

- In many coastal areas, and occasionally inland, there is a danger that over-pumping water from boreholes will cause saline water to replace the fresh water in the aquifer. Once this saline intrusion has occurred it is extremely difficult to remove the problem. Frequently, boreholes have to be abandoned and other water sources sought, often at a high cost. Aquifers can be complex and include several saline horizons at different depths. Such horizons can be detected by multilevel piezometers and water sampling systems together with conductivity/flow logging in boreholes.

Q6. What are the Limitations of Piezometers?

Ans: The use of sensors in saline water is one of the most challenging applications from the point of view of corrosion. Great care should be taken for corrosion protection in case a piezometer is used for such applications. This is a tricky application and precautions must be taken to protect both the body and the diaphragm of the sensor.

- It cannot measure the pressure of the gas or vacuum. A piezometer is ideal for measuring only the liquid pressure.

This was all about Piezometers and, I hope you found this guide pretty helpful. If you have any queries or questions, do let us know in the comments section below.