The Encardio Rite Model ELC-30S Centre Hole Load Cell is designed for civil engineering applications, featuring a high-strength martensitic stainless steel cylinder and eight strain gauges positioned 45 degrees apart to depreciate uneven and eccentric loading impact.

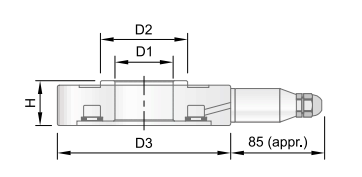

Strain Gauge Type Load Cells can be obtained in standard capacities ranging from 200-2000 kN. Load cells having an internal diameter different from our standard range are available on request.

Strain Gauge Type Load Cell: Application Areas

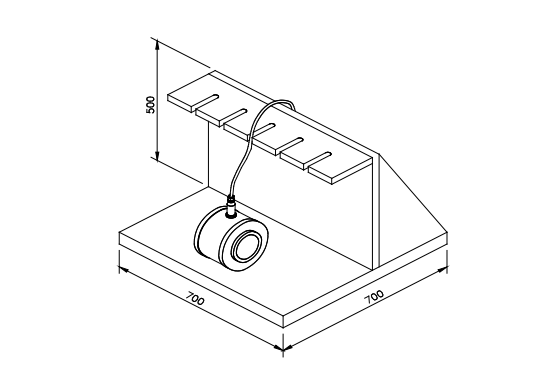

Strain Gauge Type Load Cells can be used to determine the tensile force in a ground anchor, rock bolt, cable, or tieback. It also finds its application in the measurement of compressive load between structural members, i.e. at the junction between a beam and the top of a pile strut or tunnel supports.

One of the greatest concerns of geologists, design engineers, and construction companies is the breakdown of the roof or falling of sidewall in underground cavities. As one of the most severe natural disasters, slope failures, and landslides are susceptible to happen anywhere in the world without making any distinctions.

No matter what it is, from the collapse of the roof of a mine or buckling of the sidewall of an underground powerhouse cavity to a landslide or a slope failure, the natural disaster costs an enormous amount of loss of life, property, wealth, and time.

This leads to taking preventive and corrective action to reduce the uncertainty of the doom. One such action is called anchoring where pre-stressed grouted anchors provide an active support system to the structure.

Read more: Load Cells: Types, How It Works, Applications, & Advantages

Advantage of Resistive Strain Gauge Type Load Cells

Encardio Rite Model ELC-30S Load Cell is sturdily designed to be used in a stressful environment like the one during construction activity. The main advantage of a Strain Gauge Type Load Cell when compared to a vibrating wire load cell is the ease with which the reading takes place.

The ELC-30S Load Cell can be directly read on a suitable indicator.

On the other hand, the reading for three (or six) elements of the vibrating wire load cell has to be taken separately and then finalized with the average to get the correct data. Likewise, in the case of data logging, the vibrating wire load cells require three (or six) channels.

Another advantage is that the Strain gauge-type load cell is hermetically sealed by electron beam welding with a vacuum of 1/1000 Torr inside it, making it immune to the ingress of water and most corrosive environments.

Handling of Strain Gauge Type Load Cell

The load cell is a sensitive instrument that works well in a robust environment but needs to be taken care of to function accurately. It should be dealt with with the utmost care during transportation and installation. Special attention should be paid to avoid dropping the instrument in any circumstances.

The impact generated by being dropped results in a shift of the zero reading. On the other hand, it can also lead to permanent damage rendering the instrument useless.

Strain Gauge Type Load Cell – Construction

Precision and experience go into making a perfect load cell that can measure the load with accuracy.

At the base of the stainless steel columnar element stands the strain gauges which are installed in a groove. The stainless steel diaphragm is an electron beam welded to the element to cover the groove resulting in a vacuum of around 1/1000 Torr inside the sensor.

The construction ensures that the sensor becomes immune to atmospheric corrosion and the effect of ingress of water. To provide approximately the same mV/V output for a variety of zero to full load, the sectional area of the columnar element and the depth of the groove in it is varied in different capacity load cells.

The instruments include 1 Cable joint housing and 1 Cable Gland- PG 9 along with the Load Cell.

Read more: Load Cells: Types, How It Works, Applications, & Advantages

Bearing and Load Distribution Plates

It should be kept in mind that the Centre Hole Load Cells are very sensitive and responsive to eccentric loading. The susceptibility is maintained by providing a load distribution plate of proper dimensions at the top. For some applications, a load-bearing plate may also be used at the bottom of the load cell.

Standard plates stocked by Encardio Rite have the following dimensions:

| Capacity | Bearing Plate | Load Distribution Plate |

| kN | T mm | OD mm | ID mm | Wt. kg | OD mm | ID mm | Wt. kg |

| 200 | 23 | 155 | 116 | 2 | 75 | 40 | 1 |

| 500 | 35 | 155 | 116 | 2.5 | 98 | 52 | 1.5 |

| 1000 | 45 | 200 | 150 | 5 | 135 | 78 | 3.5 |

| 1000 | 45 | 225 | 172 | 6 | 155 | 105 | 4 |

| 1500 | 55 | 225 | 165 | 8 | 150 | 85 | 5.5 |

| 1500 | 55 | 260 | 200 | 9.5 | 180 | 130 | 5.5 |

| 2000 | 65 | 260 | 195 | 12 | 180 | 105 | 9 |

| 2000 | 65 | 260 | 226 | 7 | 210 | 155 | 8.5 |

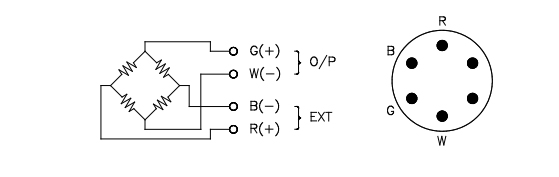

Cable Connection

The leads from the Wheatstone bridge circuit terminate on a six-pin glass-to-metal seal (2 pins blank) which is integrally electron beam welded to the stainless steel body of the center hole load cell. A cable joint housing and cable gland are provided for cable connection.

Strain Gauge Type Load Cell: Installation Requirement

The following tools/accessories are required for proper cable jointing and installation of the load cell:

- Soldering iron 25 watts, temperature-controlled

- Rosin 63/37 solder wire RF-3C, 30 swg.

- Thread sealant (Loctite 577 or equivalent)

- Cable jointing compound

- Accessories for cable jointing compound i.e. rotary tin cutter, stainless steel rod 2 mm φ, 150 mm length for stirring, spatula & pouring funnel

- Acetone (commercial)

- Toothbrush

- Cloth for cleaning (lintless)

- Wire stripper and cable cutter

- Pliers 160 mm

- Spanner 18/19

- Fixture for jointing up to five load cells

- Digital multi-meter

- Encardio Rite model EDI-53L digital indicator/logger

This was all about the Encardio Rite Model ELC-30S Strain Gauge Type Load Cell. We will be discussing the installation procedure in the next blog.