Monitoring of structures and dams has become an essential component of civil engineering as these are vital for site investigation, design verification, long-term soundness, and more importantly, for the safety of the project. To understand the structural behavior pre-construction and during operation, monitoring of dams becomes an important role.

Dam Monitoring Instrumentation is necessary as it provides information about the performance of the dam while also giving an early warning in case of any issue that may arise. The scope of instrumentation is not entirely dependent on the complexity or the size of the reservoir but also has to do with the possibility of a loss of life and property downstream.

Dam Monitoring Instrumentation includes a variety of sensors offered by Encardio Rite, each serving its purpose like measurement of pore pressure, deformation, movement, etc. With the availability of more futuristic and new-age technology, it is possible to monitor the dam from any remote location, without any hassle.

Dam Monitoring

Dam MonitoringEncardio Rite offers several surveying technologies and data transmission systems that allow you to collect readings and measurements at set intervals. If there is an increase in the predetermined level, you are quickly alerted via an SMS or alarm, allowing you to take preventive action without any accidents. The instruments also allow you to store the data by transferring it to a remote database management system which makes use of a server or cloud to keep the data safe for the required authorities to have a look.

When it comes to Dam Monitoring Instrumentation, it is important to note that every type of Dam (and even every Dam of the same type) has its own personalized set of monitoring requirements, including the type of instrumentation used. This calls for opting for the most efficient instrument from a range that is very focused and optimized.

Now that we have given you a brief introduction to dam monitoring and instrumentation, let’s take an in-depth look into why it is needed.

Dam Monitoring Instrumentation – The need for it

When it comes to the instrumentation of structures and dams, there are many naturally occurring materials with changing or varied engineering properties. A designer of geotechnical construction works with these ever-changing properties to arrive at the safest and most reliable option, observing and evaluating while making design changes.

Post-construction, dam monitoring instrumentation is carried out to assess the soundness, safety, and overall stability of the dam.

Design errors, geotechnical stability, maintenance issues, and construction material unreliability are some of the reasons why a dam can fail. Therefore, a good instrumentation program includes the following to prevent any kind of mishap:

Measurement during construction:

- To confirm and support the hypothesis and assumption of the design.

- To keep the surroundings and the main area safe during heavy construction.

- To keep an eye on the ever-changing parameters during construction.

- To assure the safety of adjacent structures and foundations during construction.

- To guarantee the performance of the new construction.

Measurement after construction is completed:

- Monitoring the performance to gauge the safety during the life of the structure.

- Measuring the effect of reservoir application on parameters like stress, strain, water pressure, inclination, deflection, and water seepage.

- Comparing the design assumptions with observed data.

- Monitoring of reservoir level and water discharge.

Measurement for research:

- Determination and measurement of design parameters.

- Examining and testing new construction materials and methods.

- Studying and observing the behavior of soil, rock, and other man-made materials that are to be used in the construction.

The Purpose of Dam Monitoring Instrumentation:

Safe operation and functioning of a dam entail economic benefits and public safety. Dam failure can cause catastrophic damage to life and property. A good instrumentation program makes use of the data to evaluate the safety of the structure by collecting data and detecting any issues at a preventable stage.

The purpose includes:

- Site investigation

- Performance monitoring

- Construction Control

- Design verification

- Safety

- Legal protection

Dam Monitoring – The Solutions

As leaders in the geotechnical field, Encardio Rite offers reliable, cost-effective, and comprehensive solutions for the monitoring of different types of dams. From supply, installation, and maintenance to seamless data collection and remote monitoring, it provides the complete spectrum of services.

Here are the solutions/sensors that are offered by Encardio Rite for online monitoring:

- Different types of geotechnical sensors are required for the accurate measurement of various parameters of the dam.

- Data Loggers with GSM/GPRS technology for automatic monitoring of geotechnical sensors.

- LoRa Nodes and Gateway offered for automatic monitoring.

- Automatic Total Stations (ATS) are used for Geodetic Monitoring.

- Laser Scanning

- Surveys conducted with the help of UAVs (unmanned aerial vehicles

- Web Data Management Services with a public cloud that alerts the authorized users and provides the data online.

Read More: Structural Health Monitoring: Instrumentation & Monitoring During Construction

Dam Monitoring Instrumentation

As we have spoken before, each dam is unique, and there is no one-size-fits-all solution that can be applied to all. It depends on the size, potential hazard, complexity, foundation, and many more aspects of the dam which are known as problems and concerns, and the degree of conservatism in the design criteria. Since Encardio Rite has been involved with the instrumentation of over 200 dams, it has made a generalized guide for different types of dams.

Dam Monitoring Instrumentation – Concrete Dams

In the table below, we talk about the different instruments required while monitoring Concrete dams along with their purpose and location. Let’s take a look.

| Instrument | Purpose |

| Pore pressure meter | Gauge the seepage of water/pore pressure of water within the cross-section of the dam |

| Stress meter | Observe the stresses in the concrete dam body |

| Pore pressure meter | To obtain the true stress, the pore pressure is monitored and then adjusted from stress meter readings |

| Joint meter – uniaxial and triaxial | Keep an eye on the joint opening between the blocks |

| Tiltmeter | Monitor the tilt of the dam |

| Strain meter rosette | Keep a check on all the deformation caused due to various reasons |

| No-stress strain meter | Observe the responses that occur because of any change in temperature, moisture, and autogenous growth in the concrete of the structure. This is adjusted from strain meter readings that provide accurate strain measurement due to stresses in the dams |

| Automatic water level recorder | Monitor the water level in the reservoir |

| Temperature meter | To prevent the micro-cracks during the casting of the concrete blocks, the temperature is monitored using the instrument. Temperature variation can cause stress on the surface of the dam that can result in material fatigue |

| Uplift pressure meter | Monitor water pressure on the base of the dam caused due to water seepage from the reservoir to the foundation. This pressure exerts a vertical upward force on the base of the dam and tries to lift it up |

| Normal plumbline (telecoordinometer) | Check the tilt of the dam that is induced by thrust applied by water pressure |

| Inverted plumbline (telecoordinometer) | Gauge the relative displacement that occurs between the foundation base rock and the dam bottom |

| Digital inclinometer or in-place inclinometer | Monitor lateral movement of the foundation |

| Borehole extensometer | Observe the relative displacement of the dam bottom concerning the foundation base rock |

| Seepage measurement device | Monitor the seepage through, around, and under embankments |

| Optical targets and robotic total stations | Monitor 3D movements or deformations |

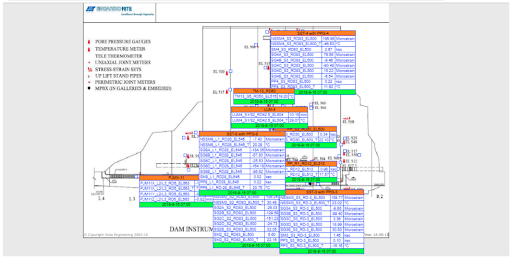

Figure: Typical instrument layout scheme with current online data from a concrete gravity dam

Figure: Typical instrument layout scheme with current online data from a concrete gravity dam| Also Read [Case Study] Bogibeel Bridge: Asia’s Second Longest Rail-Road Bridge |

Dam Monitoring Instrumentation – Earth and rockfill dam and Concrete face rockfill dam (CFRD)

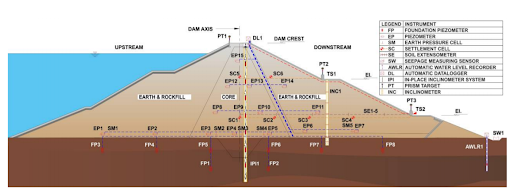

Figure: Typical instrumentation scheme in an earth and rockfill dam section

Figure: Typical instrumentation scheme in an earth and rockfill dam section| Instrument | Objective |

| Pore Pressure Meter | Observe the pore pressure of water across the section of the dam |

| Soil Pressure Meter | Monitor stress and compressive forces |

| Pore Pressure Meter | To gauge the true stress by monitoring the pore pressure and adjusting it to the stress meter reading. |

| Digital/in-place Inclinometer | Keep an eye on the lateral movement of the foundation |

| Settlement cell and magnetic extensometer | Check the settlement amount that transpires when the soil is dewatered or loaded. |

| Automatic water level recorder | Observe the reservoir water level |

| Inclinometer-cum magnetic extensometer | Take a look at the lateral movement along with the settlement |

| Soil extensometer | Gauge the soil and rock movement along with the lateral strains & settlement |

| Seepage measurement device | Monitor the amount of seepage through, around, and under embankments |

| Optical targets and robotic total stations with control box | Monitor 3D movements or deformations |

| Strain gages | Monitor strain in the concrete face |

Existing Dam

We are now well aware of the dam monitoring instrumentation for concrete and Rockfill Dams. But existing dams also need as much attention as the others do.

Similar to other structures, dams age and deteriorate with time, becoming a threat to health, property, life, and the environment. Any change in the behavioral characteristics is suggestive of a possible failure of a dam. Therefore, continuous monitoring of dams is crucial to curb these changes at early stages and prevent any accidents or mishaps.

Existing Dam Monitoring also entails the use of online monitoring systems for near real-time monitoring of installed instruments. However, the instrumentation plan for the existing dam depends on the type, health status, and the installed instruments.