Introduction to Structural Health Monitoring (SHM)

What is Structural Health Monitoring?

structural health monitoring SHM 1

structural health monitoring SHM 1Structural health monitoring is vital to avoid sudden failures and accidents. Before proceeding with any construction activity, it’s necessary to carry out the monitoring of the construction site as well as the nearby assets. Geotechnical instrumentation and monitoring supply quantitative data on the structure’s performance to aid in evaluating its safety and detecting problems at an early stage.

Structures can fail due to several reasons like design error, geological instability, poor maintenance, deterioration of construction material, etc. Structural health monitoring is a process to keep an eye on all the structures and generate early warnings to avoid mishaps.

Encardio Rite is a geotechnical instrumentation and monitoring company that provides various monitoring services along with state-of-the-art geotechnical instruments.

The Core of Structural Health Monitoring

Why is Geotechnical Monitoring important?

Geotechnical monitoring is an important matter of economic benefit as well as public safety. Sudden structural failures can threaten life and property. The main purpose of structural health monitoring is to supply quantitative performance data to the concerned authority.

Geotechnical monitoring can prove beneficial at the following stages of construction:

1. Site Investigation: Site investigation is crucial before carrying out any construction activity. It is important to check if the land is strong enough to bear the structure. Apart from this, it’s essential to check for the safety of other assets in the vicinity of the construction land. Several Structural Health Monitoring Sensors are used to characterize and determine initial site conditions. The most common parameters of interest in a site investigation are pore pressure, the permeability of the soil, slope stability, etc.

2. Design Verification: It’s quite important to verify the design of the structure. Improper design may lead to its failure. Geotechnical instruments and structural health monitoring sensors are used to verify design assumptions. Instrumentation data from the initial stage of a project may show the need or provide the opportunity to modify the design in later stages.

For example: Data obtained from reinforcement bar strain meters installed by Encardio Rite at Teesta Barrage in the left embankment led the project authorities to revise their estimates of the requirement of steel in the right embankment.

3. Construction Control: Structural monitoring is necessary to help the engineer determine how fast construction can proceed without adverse effects on the foundation soil and construction materials used. The instruments are installed to monitor the effects of construction.

For example: The temperature rise in concrete due to the heat of hydration was monitored at Sardar Sarovar Dam on the Narmada River with Encardio Rite’s temperature meters to determine the pouring temperature of mass concrete. By mixing ice flakes, the temperature of the concrete to be poured was brought down to around 15°C. This resulted in the temperature of the setting concrete not exceeding the critical 29°C, as specified and required by the Central Water and Power Research Station (CWPRS), Pune.

4. Safety: Instruments can provide early warning of impending failure. Safety monitoring requires quick retrieval, processing, and presentation of instrument data so that analyses and decisions can be made promptly. An effective action plan for implementing corrective measures can then be prepared.

| Read More: Geotechnical Instrumentation & Monitoring: Services &Types |

Advantages of Structural Health Monitoring

structural health monitoring SHM 2

structural health monitoring SHM 2Structural Health Monitoring is a critical concept and entails a list of benefits in the geotechnical world. We have already discussed the importance of Geotechnical Monitoring and now let’s list out the advantages of Structural Health Monitoring.

Structural health monitoring (SHM) is critical because:

- It can provide early warning to the concerned authorities so that they can take action well before any casualties.

- It keeps a regular check on the health of structures so that sudden failures can be avoided.

- It safeguards human life as well as the loss of property.

- It also protects the surrounding structures in the vicinity.

- It increases the lifespan of the structures.

- It reduces the long-term and short-term costs related to structural maintenance.

- It monitors the performance for safety during the life of the structure.

- It evaluates the effect of the operation of the structure on parameters like stress, strain, water, pressure, inclination, deflection, and water seepage.

- It compares the observed data with design assumptions.

- It helps with the data to plan and schedule predictive and preventive maintenance programs for the structure.

- It provides data to determine the effects of natural calamities such as earthquakes, flooding, etc. on the structure.

- Compilation of long-term and reliable data on the various elements of the plant especially foundations, anchoring systems, and containment structures.

How does Structural Health Monitoring work?

Structural health monitoring requires several geotechnical instrument installations. Structural Health Monitoring Applications are wide and present in almost every field of civil engineering. Geotechnical Sensors like strain gauges, piezometers, tilt meters, temperature sensors, pressure cells, load cells, etc. are used to measure the crucial parameters affecting the structures. These structural health monitoring sensors are installed on dams, tunnels, nuclear power plants, buildings, and monuments to measure important parameters. The measured data is logged in real-time through data loggers and displayed via a PC/laptop/mobile device at any remote location. The data loggers are capable of generating early warnings such that the concerned person can take action accordingly.

Now that you understand what is structural health monitoring, let’s take a look at how it works in different fields of application.

Structural Health Monitoring of Key Infrastructures

1. Structural Health Monitoring of Bridges

structural health monitoring SHM 3

structural health monitoring SHM 3There are numerous rail and road bridges built across the globe. They are an essential component of transportation networks and, hence, structural health monitoring of bridges is crucial. Any damage or collapse of bridges due to their deteriorating performance disrupts transportation systems and may result in the loss of life as well as property. The railway bridges are well-documented and have a laid-down system for checking and maintenance. The Ministry of Road Transport & Highways in India has established an Indian Bridge Management System (IBMS) to carry out condition surveys and instrumentation of all bridges on National Highways in India. To date, an inventory of more than 170,000 bridges and culverts has been compiled.

Bridges must function safely at all times. A large number of bridges are quite old and not designed for the heavier and faster-moving vehicular loads that they are currently subjected to.

Online Cloud-Based Web Data Monitoring Service

Encardio Rite offers public cloud-based online web data monitoring services for the safety of existing rail and road bridges. The service forms an important part of the Bridge Management System. The heart of the online structural monitoring instrumentation system is a web data monitoring service (WDMS) offered by Encardio Rite. It is a web-based data-management and presentation tool for retrieving data from the sensors through Encardio Rite's range of automatic data loggers.

WDMS consists of Drishti, data management software that acts as a data collection agent, a database server, and a web server hosted on a high-reliability server computer. The host computer periodically collects data from the remote data logger over cell phone networks. Users interact with the software using their web browser when connected to the Internet. The only requirement is that the data logger site is covered by a cell phone service provider who can provide reliable GSM/GPRS-enabled cellular data connection locally. Multiple authorized users at different locations assigned with an individual password are allowed to view any data or report from the structure simultaneously.

Details like sensor identification tag, last recorded sensor reading, and values of programmed alert levels can be viewed on the first page of the site that shows the location of installation. If any of the alarm levels exceeds, the sensor location turns to a red dot. Clicking the pop-up table brings up an associated data window where the sensor data can be seen either as a table or as a graph. Site administrators can set alarm limits which are generally considered as “alert level” and “evacuate level”.

WDMS can also be programmed to send SMS alert messages or e-mails to selected users as soon as any sensor data crosses its predefined alarm levels, either while going above or below the alarm level.

Bridge Monitoring Instrumentation Scheme

Taking the application of Structural Health Monitoring forward. there are two types of instrumentation schemes to monitor the health of the bridges.

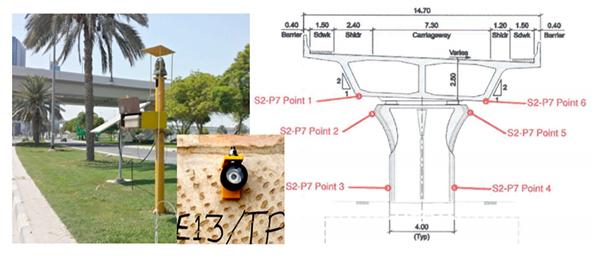

structural health monitoring SHM 4Figure 1: Online web-based monitoring of surface parameters like tilt, crack, load, strain, vibrations, and subsurface parameters like lateral movement, settlement, and piezometric pressure.

structural health monitoring SHM 4Figure 1: Online web-based monitoring of surface parameters like tilt, crack, load, strain, vibrations, and subsurface parameters like lateral movement, settlement, and piezometric pressure. structural health monitoring SHM 5Figure 2: Online web-based monitoring of lateral movement and settlement using robotic total stations and prism targets

structural health monitoring SHM 5Figure 2: Online web-based monitoring of lateral movement and settlement using robotic total stations and prism targetsStructural health monitoring examples: The picture on the left is a typical installation of a robotic total station to automatically gather data from prism targets installed on the structure of a bridge. The structural health monitoring sensor shown in the middle is a mini prism target. The figure on the right shows points at which prism targets may be installed on a typical bridge. More than one robotic total station may be required for proper monitoring of a structure.

| Read More: A Guide on Geotechnical Instruments: Types, & Application |

Screenshots of some sample long-term monitoring data

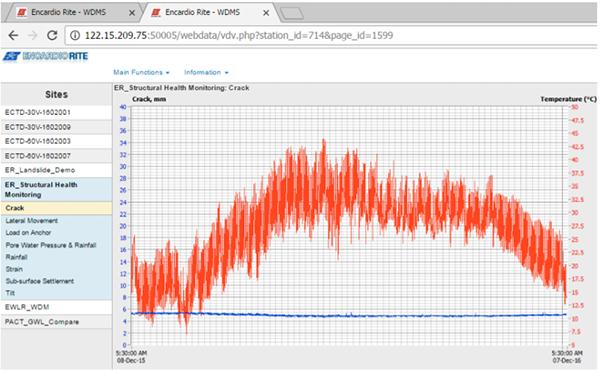

structural health monitoring SHM 6

structural health monitoring SHM 6The figure above shows structural crack monitoring over one year using the Encardio Rite Model EDJ-40V crack meter. The structural health monitoring example shows the crack opening in blue and the variation in temperature in red. The initial opening of the crack gauge was set at 5.12 mm.

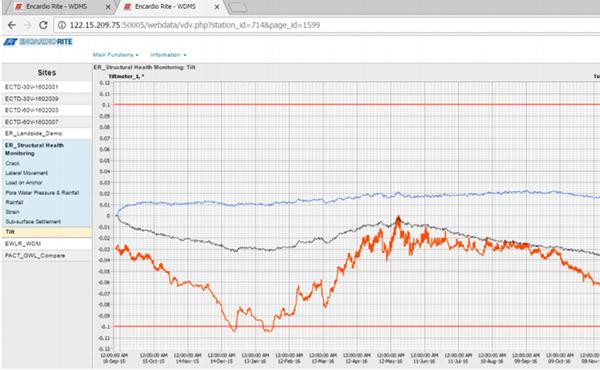

structural health monitoring SHM 7

structural health monitoring SHM 7The above image shows the structural tilt monitoring of the bridge from September 12, 2015, to December 8, 2016, using the Encardio Rite Model EAN-92M biaxial tilt meter. Tilt variation in the two directions is shown by the blue and black lines. The maximum change in tilt recording during this period is 0.04 deg.

The two horizontal red lines at the top and bottom are the alarm limits set at ± 0.1 deg. The red line gives the temperature variation during this period.

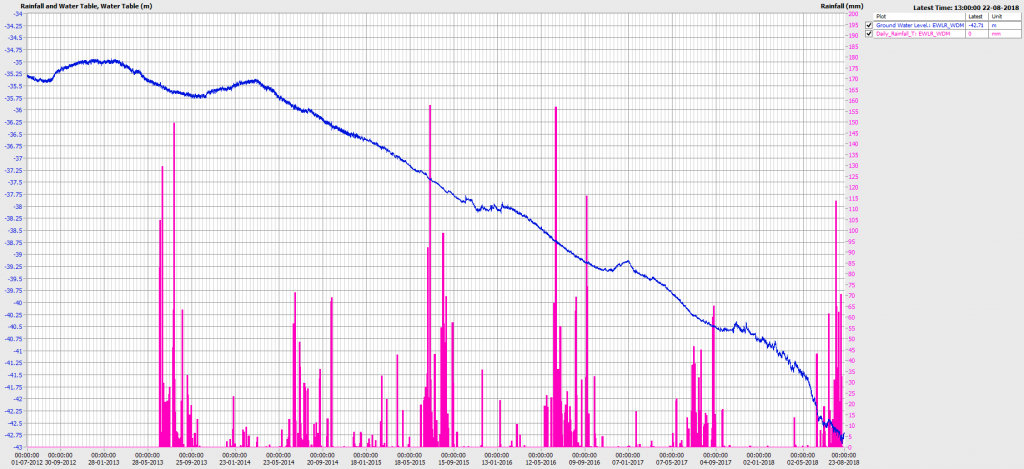

structural health monitoring SHM 8

structural health monitoring SHM 8The above structural health monitoring example shows monitoring of groundwater level along with daily rainfall for two years. Piezometric pressure is in blue and daily rainfall is in purple. The maximum rainfall recorded on any day during this period is 73 mm. Ground water table variation during this period has been between 50 and 52 m of water column.

Structural Health Monitoring Sensors used are Encardio Rite piezometer Model EPP-30V and Rain Gauge Model ERG-200 tipping bucket type.

structural health monitoring SHM 9

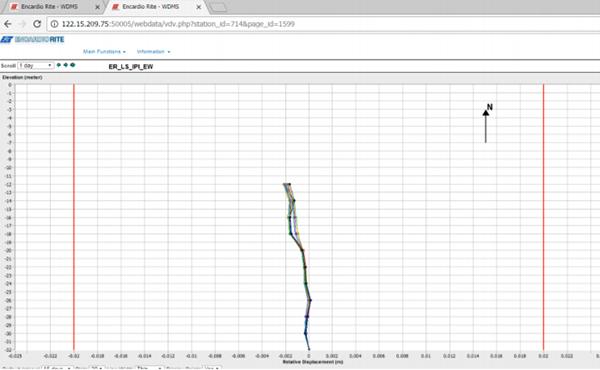

structural health monitoring SHM 9The above image shows the monitoring of subsurface lateral movement for 300 days. Encardio Rite EAN-52MV vertical in-place inclinometer system has been used for monitoring lateral movement. A total of 11 sensors have been installed in the borehole from a depth of 12 m to 32 m. The maximum displacement recorded during this period has been a little more than 2 mm.

The two vertical lines are alarm values set at ± 20 mm. Readings are retrieved once an hour and transmitted four times a day for online web-based monitoring.

structural health monitoring SHM 10

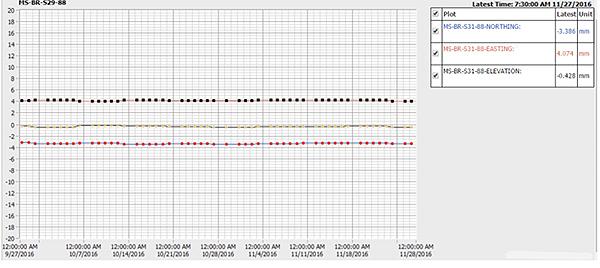

structural health monitoring SHM 10Automatic monitoring of Northing, Easting, and Elevation using a robotic total station and a prism target on a bridge pier for around two months. This is the end of Shm of bridges. Let’s now take a look at tunnels.

2. Structural Health Monitoring of Tunnels

structural health monitoring SHM of Tunnel

structural health monitoring SHM of TunnelAnother application of Structural Health Monitoring is focused on underground tunnels. Encardio Rite offers a comprehensive web-based monitoring solution for the long-term safety monitoring of tunnels. It manufactures a wide range of sensors that have a proven track record for reliability and long-term performance under harsh conditions. It also offers advanced monitoring technologies such as automatic 3D deformation monitoring using ATS, laser scanning, and aerial surveys using drones for keeping a tab on the structural health of tunnels and appurtenant structures.

Structural Monitoring Solution for Tunnels

WDMS – Web-based Data Monitoring Solution

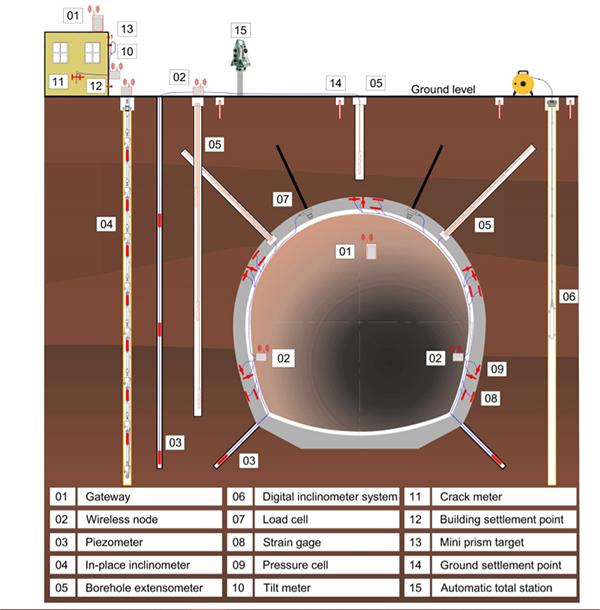

Web-based data monitoring solution for any type of tunnel construction such as NATM, TBM tunneling, cut & cover, micro-TBM/pipe jacking, etc. essentially comprises the following structural health monitoring sensors:

- Model EAN-52M vertical in-place inclinometer system with several biaxial probes with SDI-12 output mounted vertically in a borehole.

- These are connected in a daisy chain manner with a single output cable for continuously monitoring subsurface lateral movements.

- Model EPP-30V vibrating wire piezometer with model ESVI-01-01 or ESVI-10VB SDI12 interface box for monitoring pore pressure variations.

- Model EDS-70V vibrating wire type multiple point borehole extensometer (with ESVI-01-04 SDI-12 interface box) for monitoring subsurface settlement and lateral movement at specified depths.

- Model EAN-92M-B or EAN-93M-B biaxial tiltmeter with SDI-12 output mounted at one or more locations on the structures within the zone of influence to record changes in tilt.

- Model EDJ-40V vibrating wire crack meter (with ESVI-01-01 SDI-12 interface box) for monitoring displacement/opening of existing cracks in structures within the zone of influence.

- Model ELC-30S/ELC-30SH resistive strain gage type center hole load cell (with ESBI-10 SDI-12 interface box) for monitoring tension in anchors and rock bolts.

- Model ELC210S/ELC-150SH resistive strain gage type strut load cell for monitoring loads on struts.

- Model ESC-30V vibrating wire shotcrete pressure cell or model EPS-30V vibrating wire concrete pressure cell (with ESVI-01-01 SDI-12 interface box) for monitoring radial and tangential stress in shotcrete lining or concrete precast segments.

- Model EDS-20V-E/EDS-20V-AW vibrating wire strain gauges (with ESVI-01-01 SDI12 interface box) for monitoring strains in tunnel linings and concrete precast segments.

- Model EBS-16 building settlement points for monitoring the settlement of structures using a digital level.

- Model ESMP-10C2 or EPS-12-60 surface settlement points for monitoring settlement of ground above the tunnel.

- Encardio Rite Model EAN-26-MV manual inclinometer system consisting of a bi-axial digital inclinometer probe, operating cable on a reel with Bluetooth transceiver, and a smartphone data logger with inclinometer application.

- RF wireless nodes for collecting, storing, and transmitting data from analog and digital sensors.

- These could be single & multichannel. RF Gateways with integrated GSM/GPRS modem for enabling cable-free wireless transmission of data. Refer to the figure below showing installed sensors in a typical tunnel section with RF data transmission.

- Encardio Rite Model ESDL-30 data logger for the SDI-12 output sensors, with integral GSM/GPRS for wireless data transmission.

- Encardio Rite Online Web Data Monitoring Service (WDMS) that provides data access (with alarms) to authorized users at different geographical locations, on their computers/laptops.

Geometry Control

Encardio Rite offers TunnelCAD PC and TunnelCE field software. Together these provide a complete solution for graphical and numerical comparison of design vs/measured cross sections of tunnels.

The following results could be obtained using a variety of inputs such as project data, import from DWG/DXF, direct communication from tunnel CE, etc.

- Profile evaluation with graphical and/or numerical data analysis.

- Volume computations between theoretical and measured lines.

- Layer thickness analysis.

- Under and over break.

- Automatic creation of 3D visualization from any measured line.

- As-built documentation.

Laser Scanning

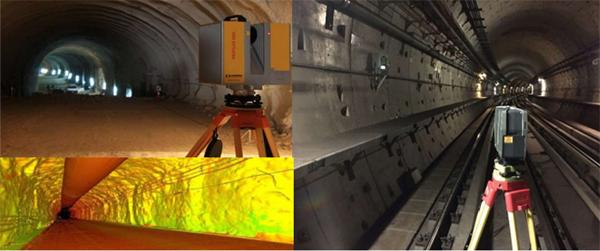

Structural health monitoring SHM of Tunnel (Laser Scanning)

Structural health monitoring SHM of Tunnel (Laser Scanning)Laser scanning is an advanced method of surveying and conducting geometric documentation of buildings, architectural and archaeological monuments, engineering projects, or other construction works and objects that require a high degree of analysis, are difficult to reach or gain access to, or are not to be touched. Recent developments, especially in the software, have made it a very convenient and cost-effective tool to accurately monitor structural deformations in 3D. Accuracy of up to 2-3 mm is possible using the method. Due to the lighter nature of the new software, it takes significantly less time to process the results and make the same available online, almost in real-time.

It is based on exceptionally dense mapping of 3D coordinates of the points on the surface that are to be surveyed, taken at speeds ranging from a few thousand up to a million points per second. Depending on the object (size, shape, desired accuracy), laser scanning may be airborne or terrestrial, static or mobile, autonomous, or in combination with other standard topographic methods. Completion of the fieldwork results in a geo-referenced point cloud which, due to its great density and its ability to bear information on the reflectivity and/or the color of each point, comes close to the term, “virtual reality”.

Depending on the case and the user’s needs, horizontal, vertical, or diagonal sections, aspects, images, videos, ortho-photographs, surface expansions, interval curves, 3D models, determination of distortion as well as several other analyses derived from the scanner’s operations in the non-visible spectrum, can be produced.

Laser Scanning of a Tunnel - Structural Health Monitoring (SHM)Figure 3: Laser scanning of a tunnel

Laser Scanning of a Tunnel - Structural Health Monitoring (SHM)Figure 3: Laser scanning of a tunnelTo summarize, the results of laser scanning give us:

- Surveying of current state or ‘as constructed’ state

- Virtual reality creations; Virtual tour videos

- Geometric documentation of the structure

- Quantitative calculation

- Inspection of free passage space – determination of bottlenecks

- Creation of 2D & 3D products (sections, facets, 3D models, etc.)

- Identification of deformations – discrepancies

Aerial Mapping using Unmanned Aerial Vehicles (UAV/Drone)

Aerial Mapping - Structural Health Monitoring (SHM)

Aerial Mapping - Structural Health Monitoring (SHM)Inspection of huge and complex structures like tunnel construction sites requires a high degree of analysis but at times is difficult to reach or gain access to. The use of Unmanned Aerial Vehicles (UAV)/Drones is best suited for such applications. UAVs/Drones are unmanned and remotely piloted aircraft that follow a pre-programmed path for takeoff, flight, and landing. These aircraft are equipped with HD/IR/Thermal cameras that compute aerial images and videos over a defined area at a specified height.

Using UAVs/drones to video, model, and scan for cracks, erosion, corrosion, and defects in areas that would otherwise require the inspector to use a rope/harness or erect access scaffolding, is a safer, faster, and smarter choice. Large sites with complex structures necessitate aerial photogrammetry avoiding expensive ground-based surveys. This technology is useful during the construction process also- as the development occurs, managers have difficulty maintaining a true picture of the site.

With UAV-based mapping at regular intervals, this information gap can be closed.

Results from UAV/drone are in the following forms:

- Photos & Orthophotos

- Mesh 3D Models & Texture 3D Models

- Drawings

- Videos – Presentations

- Contour maps

- Slope maps

- Area – Volumetric calculations

Automatic 3D deformation monitoring system

Automatic 3D Deformation Monitoring System - Structural Health Monitoring (SHM)

Automatic 3D Deformation Monitoring System - Structural Health Monitoring (SHM)The real-time 3D deformation structural monitoring system is a systematic tracking of any alteration that may take place in the shape or dimension of the tunnel as a result of stress, load, aging, etc., or of any structure located within the zone of influence of the tunnel construction. The above deformation monitoring system consists of high-accuracy automated total stations (ATS) that can auto-target recognition (without any human interference). Each ATS has a dedicated control box that includes a computer running special software.

This control box manages the total station and schedules the frequency of the measurements, the addition or subtraction of monitor benchmarks, the filters of acceptance or repetition of each measurement, the atmospheric corrections in distance measurements, the calculation and repositioning of the total station, etc.

The whole system can be controlled/re-configured remotely after installation at the site. The on-site system transmits the collected raw data to a remote server/computer via GSM/GPRS. Raw data is processed into meaningful results and presented in the WDMS. The system has the facility of alert notifications through SMS and (or) e-mail to the authorized team for any result exceeding present alarm and critical levels.

The system provides accurate, continuous, real-time data, eliminating any human error/delay in manual data. The raw data is processed and analyzed and the result is majorly used for predictive maintenance, alarming for safety.

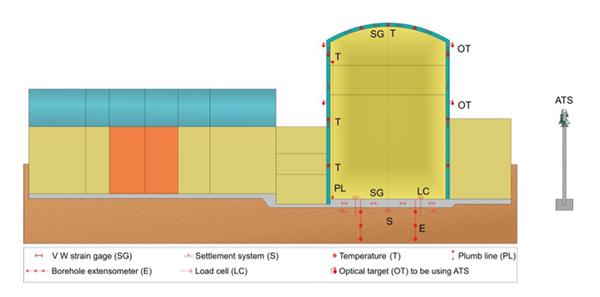

Tunnel Monitoring Instrumentation Scheme

Tunnel Instrumentation with RF-enabled Data Transmission - Structural Health Monitoring (SHM)Figure 4: Tunnel instrumentation with RF-enabled data transmission

Tunnel Instrumentation with RF-enabled Data Transmission - Structural Health Monitoring (SHM)Figure 4: Tunnel instrumentation with RF-enabled data transmission

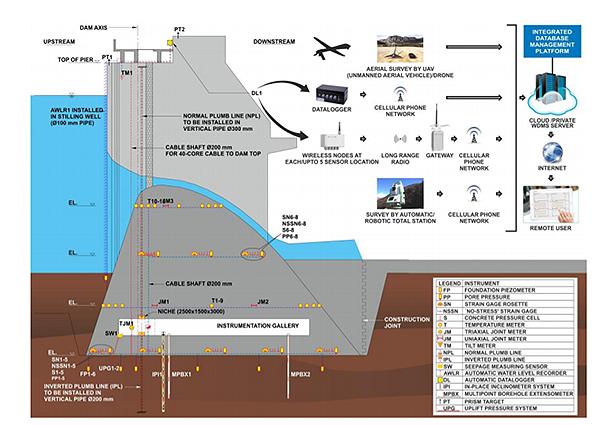

3. Structural Health Monitoring of Dams

structural health monitoring SHM of Dams

structural health monitoring SHM of DamsThe Applications of Structural Health Monitoring are crucially and widely used to monitor dams. Dam monitoring instrumentation plays a key role in safety monitoring for dams and people, providing necessary information on the performance of the dam and detecting problems at an early and preventable stage. The extent and nature of instrumentation depend not only on the complexity of the dam and the size of the reservoir but also on the potential for loss of life and property downstream. This information is critical for the dam’s owner who is directly responsible for any consequences of its failure.

Instrumentation includes different types of sensors used for measuring pore pressure, water flow, lateral movement, deformation, stress, strain, and temperature, installed in the dam and its auxiliary structures. It also includes geodetic targets measured using surveying techniques.

Monitoring Solutions for Dam

structural health monitoring SHM of Tunnel - Monitoring Solutions

structural health monitoring SHM of Tunnel - Monitoring SolutionsEncardio Rite offers a simple-to-use, comprehensive, and cost-effective solution to the user for online monitoring of different types of dams and their auxiliary structures. This includes supply, installation, calibration, maintenance, data collection, and a web-based data monitoring service that provides information in the most suitable forms for easy interpretation of the monitoring data. Dams age and deteriorate with time posing a potential threat to life, health, property, and environment.

The safe functioning of dams is important. Changes in behavioral characteristics may be indicative of an impending failure of a dam. Continuous monitoring of dams is essential to detect such changes at early stages and to enhance response time to prevent disasters. This calls for online monitoring systems that are commissioned for near real-time structural health monitoring of the installed instrumentation.

The instrumentation plan will depend on the type and health status of the dam and the existing working instruments installed in the dam. Replacement of existing faulty instruments to the extent necessary and practicable and adding state-of-the-art new instrumentation systems depending on the feasibility and health of the dam should be taken up to ensure an effective monitoring system.

The following solutions are available with Encardio Rite for online monitoring:

- Structural Health Monitoring Sensors to measure all relevant parameters required to monitor different types of dams

- Automatic monitoring of geotechnical sensors with SDI-12 digital interface using SDI-12 data logger with GSM/GPRS telemetry

- Automatic monitoring of geotechnical sensors using LoRa nodes and gateways

- Geodetic monitoring with automatic total stations (ATS) with GSM/GPRS telemetry

- Laser scanning

- Survey by UAVs (unmanned aerial vehicles) or drones

- Public cloud-based web data management service (WDMS) that provides data online (with alarms) to authorized users at different locations on their computers/mobile devices.

Dam Monitoring Instrumentation Scheme

Each dam is a unique situation and requires an individual solution for its instrumentation requirements. There are no simple rules for determining the appropriate level of instrumentation and monitoring because it depends on the size and hazard potential classification of the dam, the complexity of the dam and foundation, known problems and concerns, and the degree of conservatism in the design criteria. Based on our vast experience in instrumenting over 200 dams, a few typical instrumentation schemes for online monitoring of different types of dams are given below:

Concrete Dam

Concrete Dam - Structural Health Monitoring (SHM)Figure 5: Instrumentation Scheme of a concrete gravity dam

Concrete Dam - Structural Health Monitoring (SHM)Figure 5: Instrumentation Scheme of a concrete gravity damThe table below gives an insight into the purpose of the different instruments, along with their locations.

Typically three or more different blocks are instrumented in a concrete dam. The structural health monitoring instrumentation scheme of the blocks may differ from each other, depending upon design considerations and other factors.

| Purpose | Instrument | Location |

| Monitor pore pressure or seepage of water through the cross-section of the dam | Pore pressure meter | Dam blocks at different elevations |

| Monitor stresses in the concrete of the dam body | Stress meter | Near the foundation where the height of the dam is maximum (can be just below the gallery) |

| Monitor pore pressure to adjust it from stress meter readings to get true stress | Pore pressure meter | Near stress meters |

| Monitor joint opening between the blocks | Joint meter – Uniaxial and triaxial | Between the concrete blocks |

| Monitor the tilt of the dam | Tilt meter | Dam block, at the top |

| Monitor deformation due to all causes – including those due to stress | Strain meter rosette | In the dam body – in a group of five strain gages at angles of 0°,45°,90°, and 135° in one plane and one strain gage at right angles to this plane |

| Monitor deformation due to changes in temperature, moisture, or autogenous growth in the mass concrete of the structure. Adjusting this from strain meter readings gives strain due to stresses in the dams | No-stress strain meter | Near strain meter rosette -inside the no-stress container |

| Monitor the water level in the reservoir | Automatic water level recorder | The upstream side of the dam |

Monitor the temperature of concrete during the casting of the concrete blocks to prevent undesirable micro-cracks.

Temperature variation is also one of the major factors causing stress on the surface of the dam that results in material fatigue | Temperature meter | Dam blocks and spillway |

| Monitor water pressure on the base of the dam caused due to water seepage from the reservoir to the foundation. This pressure exerts a vertical upward force on the base of the dam and tries to lift it up | Uplift pressure meter | In the dam Gallery – downwards – with a stop valve on the uplift pressure pipes, which is opened to release the water and reduce pressure on the base of the dam. |

| Monitor tilt of dam – caused by thrust applied by water pressure on the dam | Normal plumbline (telecoordinometer) | Blocks |

| Monitor relative displacement between the dam bottom and the foundation base rock | Inverted plumbline (telecoordinometer) | In the same block as that of the Normal plumbline |

| Monitor lateral movement of the foundation | Digital inclinometer or in-place inclinometer | Dam foundation with top in cross or transverse gallery |

| Monitor vertical displacement of the dam bottom with respect to the foundation base rock | Borehole extensometer | Dam foundation with the top assembly in cross or transverse gallery |

| Monitor the amount of seepage through, around, and under embankments | Seepage measurement device | The downstream side of the dam |

| Monitor 3D movements or deformations | Optical targets and robotic total stations with control box | Dam surface |

| Monitoring of construction progress; Monitoring and inspection of dams for maintenance | Unmanned Aerial Vehicle (UAV) equipped with a high-performance camera or laser scanner | Aerial |

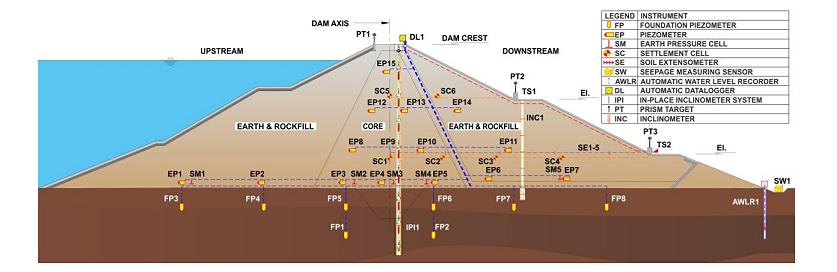

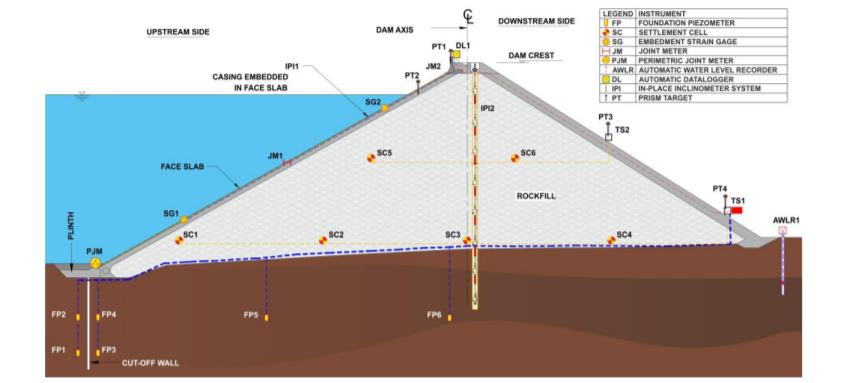

Earth and rockfill dam and concrete-faced rockfill dam (CFRD)

Earth and Rockfill Dam section - Structural Health Monitoring (SHM)Figure 6: Typical instrumentation scheme in an earth and rockfill dam section

Earth and Rockfill Dam section - Structural Health Monitoring (SHM)Figure 6: Typical instrumentation scheme in an earth and rockfill dam section Concrete face rockfill Dam Section - Structural Health Monitoring (SHM)Figure 7: Typical instrumentation scheme in a concrete face rockfill dam section

Concrete face rockfill Dam Section - Structural Health Monitoring (SHM)Figure 7: Typical instrumentation scheme in a concrete face rockfill dam section

| Purpose | Instrument | Location |

| Monitor pore pressure or seepage of water through the cross-section of the dam | Pore pressure meter | Dam body at different elevations. Also in the d |

| Monitor compressive forces and stress | Soil pressure meter | Dam body at different elevations near the foundation where the height of the dam is maximum (can be just below the gallery) |

| Monitor pore pressure to adjust it from stress meter readings to get true stress | Pore pressure meter | Near soil pressure meters |

| Monitor lateral movement of the foundation | Digital inclinometer or in-place inclinometer | Across the dam body; from the base of the dam to the top |

| Monitor the amount of settlement that occurs when soil is loaded or dewatered | Settlement cell and magnetic extensometer | Across the dam body; from the base of the dam to the top |

| Monitor the water level in the reservoir | Automatic water level recorder | The upstream side of the dam |

| Monitor lateral movement along with the settlement | Inclinometer-cum magnetic extensometer | Dam body, towards the downstream side, with top inaccessible area to take manual readings |

| Monitor soil or rock movement, lateral strains, and settlement | Soil extensometer | Dam body from upstream side to downstream side |

| Monitor the amount of seepage through, around, and under embankments | Seepage measurement device | The downstream side of the dam |

| Monitor strain in the concrete face | Strain gages | The concrete face of CFRD |

Note: Some of the structural health monitoring methods mentioned in the previous table for concrete dams e.g. 3D deformation monitoring using robotic total stations and UAV surveys can also be used for monitoring earth & rockfill and CFRD dams.

4. Structural Health Monitoring of Buildings

structural health monitoring SHM of Buildings

structural health monitoring SHM of BuildingsIf we are talking about Structural Health Monitoring Applications, it is essential to mention the buildings.

Encardio Rite offers online web-based monitoring services for the following:

- Safety of existing multiple-storey buildings, hotel complexes, corporate offices, and buildings of critical importance

- Safety of old and depleted buildings and structures subject to long-term movement or degradation of materials

- Safety of buildings, monuments, and structures during nearby construction activity (like the construction of Metros, deep excavation for high-rise buildings, etc.)

- Safety of monuments and structures of historical importance

- Safety of buildings and structures in hills and landslide-prone areas

Structural monitoring solutions for buildings/monuments

Monitoring the health of infrastructure is an extremely crucial and critical procedure. For buildings, structures, bridges, etc., it is recommended that Structural Health be continuously monitored to ensure proper maintenance and safety of man and material.

A basic system offered by Encardio Rite that can be used for most structures essentially consists of the following Structural Health Sensors:

- Encardio Rite model EAN-92M-B biaxial tiltmeter mounted at one or more locations on the structure. The tilt meter should ideally be installed at an indoor location or in the shade to prevent the effect of large temperature fluctuations on the monitored results. Readings should possibly be retrieved in the morning hours when temperature-induced stresses in the buildings are minimal.

- Encardio Rite model ESDL-30 SDI-12 data logger with integral GSM/GPRS modem for storing and transmitting data to a server with the service provider.

- Encardio Rite online web data monitoring service (WDMS).

Some other instruments may be used depending on the structure to be monitored and its location. The structure health monitoring sensors include:

- Encardio Rite model EDJ-40V vibrating wire crack meter (with ESVI-01-01 SDI-12 interface box) to monitor structural cracks

- Encardio Rite model EPP-30V vibrating wire piezometer (with ESVI-01-01 SDI-12 interface box) to monitor sub-surface water level

- Encardio Rite model EAN-52MV vertical in-place inclinometer system with several biaxial probes (with integral SDI-12 protocol) mounted vertically in a borehole to monitor subsurface lateral movements around the structure.

- Instruments used for surface as well as subsurface monitoring of structures are illustrated on the next page.

- Subsurface monitoring gives important information on ground/soil movement which may affect the stability of the structure.

Crack width

With time cracks develop in buildings, structures, and monuments. Monitoring changes in their width provides important information. To online monitor changes in crack width, a suitable sensor is the model EDJ-40V vibrating wire crack meter with SDI-12 interface. Users may use several of these at representative locations to monitor the development of cracks in buildings with time. The crack gauge also has a thermistor incorporated so that temperature can be simultaneously monitored.

Piezometer

Encardio Rite model EPP-30V piezometer with SDI-12 interface is recommended for online monitoring of groundwater pressure/level near the structure. An online piezometric pressure monitoring system provides very important information on safety, especially during the rainy season. Take, for example, any building or structure on a hill.

In-place inclinometers for lateral movement in the ground

In-place inclinometers (IPI) are used for continuous subsurface monitoring of the ground's lateral movement, which may affect the structure's safety. For example, take a multi-story building to be constructed in an area having a lot of construction around.

The construction of the multi-story building will require a deep foundation. In such cases, IPIs installed in the ground between the excavations and adjoining structures help in controlling the construction process to ensure safety. IPIs with Web Data Monitoring Service are also used in hilly areas and mountains where buildings and structures are constructed on slopes and need online monitoring for safety.

For online monitoring of lateral movement in boreholes, Encardio Rite offers a model EAN52MV Vertical In-place Inclinometer System with SDI-12 interface sensors.

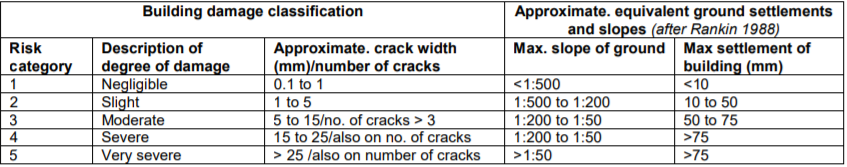

Reference guidelines for building damage classification

5. Structural Health Monitoring of Nuclear Power Plants

structural health monitoring shm of Nuclear Power Plant

structural health monitoring shm of Nuclear Power PlantStructural Health Monitoring is also applied in the field of Power Plants. Encardio Rite offers online web-based monitoring services for the long-term safety monitoring of Nuclear Power Plants. It has a wide range of geotechnical sensors that have a proven track record for reliability and long-term performance under harsh conditions. It also offers newer monitoring technologies such as automatic 3D deformation monitoring using ATS, laser scanning, and aerial surveys using drones for keeping a tab on the structural health of Nuclear Power Plants.

Structural Monitoring Solutions for Nuclear Power Plants

Surface and subsurface sensors that can be used for safety monitoring of Nuclear Power Plants are given below with a typical location plan. It is noteworthy that subsurface monitoring gives important information on the ground/soil movement which may affect the stability of the plant’s structure.

Structural Monitoring Solutions for Nuclear Power Plants - Structural Health Monitoring (SHM)

Structural Monitoring Solutions for Nuclear Power Plants - Structural Health Monitoring (SHM)- Encardio Rite Model ELC-30S resistive strain gage type center hole load cell (with ESBI-10 SDI-12 interface box) for monitoring tension in prestressing cables and ground anchors used for stabilizing the foundation.

- Encardio Rite Model EDS-11V hermetically sealed vibrating wire strain gage or Model EDS-21V extended range vibrating wire strain gage (with ESVI-01-01 SDI-12 interface box) embedded in the walls and the base slab of the plant’s structure to monitor change in strains. Stress can be derived from the strain data.

- Encardio Rite Model ETT-10V vibrating wire temperature sensor (with ESVI-01-01 SDI-12 interface box) embedded in the walls and the base slab plant’s structure to monitor the temperature.

- Encardio Rite Model EGS-30V settlement measurement system (with ESVI-01-01 interface box) to monitor settlements occurring in the base slab.

- Encardio Rite Model EDS-70V electrical multipoint borehole extensometer system with vibrating wire displacement transducers (with ESVI-01-01 SDI-12 interface box) for monitoring relative vertical movements.

- Encardio Rite Model EDS-50 normal plumb line with telecoordinometer (with ESDI-420I SDI-12 interface box) to monitor relative horizontal movements.

- Encardio Rite model ERT-20P2 mini prism target to be installed on the fascia of the structure to monitor 3D deformations using an automated total station (ATS).

The following sensors may also be considered for structural health monitoring:

- Encardio Rite Model ESDL-30MT SDI-12 data logger with in-built tilt meter to measure and log tilt data (to be installed ideally at an indoor location or in the shade to prevent the effect of large temperature fluctuations on the monitoring results).

- ESDL-30MT is provided with an integral GSM/GPRS modem for storing and transmitting data to a central server.

- Encardio Rite Model EDJ-40V vibrating wire crack meter (with ESVI-01-01 SDI-12 interface box) to monitor structural cracks.

- Encardio Rite Model EAN-93M-B biaxial tiltmeter with an integral SDI-12 interface

- Encardio Rite Model ESDL-30 data logger for the above-mentioned sensors, with integral GSM/GPRS modem for storing and transmitting data to a server.

- Encardio Rite online web data monitoring service (WDMS) that provides data online with alarms to authorized users at different locations, on their computers/laptops.

Online monitoring using the above instrumentation gives a timely warning of impending danger. The purpose is to assist and inform the stakeholders about the continued performance of structures under gradual or sudden changes to their state. The main factors affecting the performance are degradation of the structure with age, undue settlement/tilt due to soil conditions or nearby construction activity, vibrations due to heavy machinery, groundwater level, atmospheric conditions, etc. This may be reflected in abnormal changes in the monitored values

The Future of Structural Health Monitoring SHM: Technological Innovations

What is the future of Structural Health Monitoring?

future of structural health monitoring SHM

future of structural health monitoring SHMWe have discussed the application of Structural Health Monitoring in great detail. Now let’s take a look into its future. OPSIS, the unique software developed by Encardio Moniterra Group is the future of Structural Health Monitoring. The terrestrial Laser Scanner or LiDAR has been used in the fields of surveying engineering and geomatics extensively as the evolution and improvements in its technology allowed the collection of increasingly more accurate data sets.

Despite the benefits of LiDAR over other data-collecting methods, such as the remarkably higher amount of data collected for the same area in reduced periods without the need to place targets, the field of Structural Health Monitoring has remained one of the few unable to implement this technology. The reason behind this is none other than the vast amounts of data that LiDAR provides. However, this advantage becomes a weakness at the post-processing stage, where the analysis of large data sets acquired regularly presents a challenge.

Hence, OPSIS was developed to overcome the impediments previously described. The idea within its core is to perform operations over the raw data provided by LiDAR to get a significantly smaller data set.

For the results obtained from the analysis of this sub-dataset to be equivalent to those we would obtain evaluating the original, the operations involved must ensure to preserve the spatial information contained within the input data.

| Read More: OPSIS: The Smart Solution For Laser Scanning Monitoring |