Nuclear Power Plants! You must have heard about these thermal power stations that are built all over the world. Did you know that around 11% of the world’s electricity is generated by about 449 nuclear power reactors? According to the World Nuclear Association, in the year 2020, nuclear plants supplied 2553 TWh of electricity.

In the 60 years of generating nuclear energy, the United States of America has produced clean and carbon-free electricity. It also said that each year, about a fifth of the country’s electricity is produced from nuclear power.

Historically, the first operational nuclear power plant became functional on June 27, 1954. In the Soviet Union, Obninsk Nuclear Power Plant became the first nuclear power plant to generate electricity for a power grid.

Nuclear power plants are thermal stations that have nuclear reactors as their main heat source. However, due to the highly regulated environment of nuclear power plants, paramount importance has to be given to careful planning and equally careful execution of the instrumentation and monitoring solutions.

Nuclear power plants are critical structures whose monitoring and instrumentation have to be performed during construction and over the life of the facility. Let’s dig deeper into the purpose and importance of nuclear power plant monitoring systems.

Purpose of Nuclear Power Plant Monitoring System

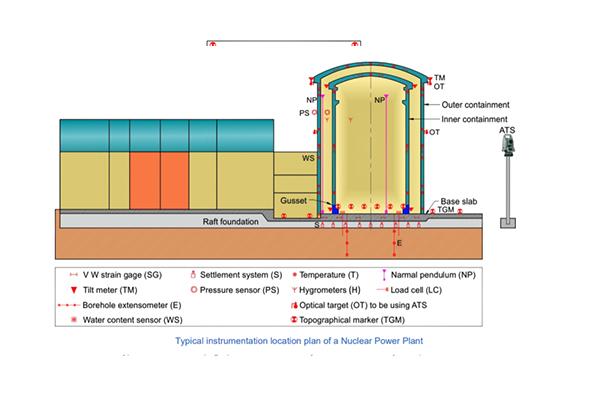

The structure of the nuclear power plant is fairly standard in the nature of its design. The geotechnical and structural design parameters should be monitored to confirm that standard design parameters envelope site-specific parameters. The monitoring solutions provide significant information in cases where site-specific conditions exceed standard design parameters.

The geotechnical monitoring solutions are useful during construction as well as after construction for long-term monitoring when the facility is operational. A geotechnical instrumentation plan, including “alert” or “trigger” values that give instant information on actions to be taken, is part of monitoring efforts.

Monitoring the structural integrity of the containment building and individual/common raft is most important as it assists in assessing the mechanical behavior of the building at various stages, like:

- During construction

- During the acceptance test and the periodic airtightness tests

- Normal operation

- After exceptional events like earthquake

If there is any structural deterioration and damage in the plant’s structure, there is a big possibility that the radioactive fuel can spread and contaminate a vast geographical area. It would become very difficult to get rid of its deadly and dangerous effects. Hence, it is very important to implement various geotechnical instrumentation along with non-contact deformation and aerial surveys.

With over 57 years of experience in manufacturing and supplying geotechnical instruments and online monitoring solutions, Encardio Rite has carved its name. Encardio Rite is known for providing world-class digital sensors, automatic dataloggers, Data Management Systems (Drishti from Encardio Rite and Simon-e from SITES), etc.

| Also Read Krško Nuclear Power Plant: Geotechnical Instrumentation for Krsko Project |

Structural Nuclear Power Plant Monitoring Solutions

When it comes to nuclear power plant monitoring, Encardio Rite offers a complete online web-based monitoring solution including geotechnical as well as structural instrumentation. The Instrumentation and Control systems produced by Encardio Rite have a proven track record for reliability and long-term performance under harsh conditions.

Encardio Rite also offers advanced solutions such as automatic 3D deformation monitoring using ATS, laser scanning with advanced deformation monitoring software, and aerial surveys using drones.

A typical location plan is given below showing surface and subsurface sensors that can be used for safety monitoring of nuclear power plants.

Typical instrumentation location plan of a Nuclear Power Plant

Typical instrumentation location plan of a Nuclear Power PlantFor settlement and deformation monitoring of the nuclear island raft, Encardio Rite can provide the following instruments:

1. Geodetic targets:

Encardio Rite model EPS-12-60 topographical marker/pavement settlement points and model ERT-20P2 mini prism target can be installed for monitoring settlement.

ERT-20P2 prism target

ERT-20P2 prism targetERT-20P2 prism target

2. Settlement system:

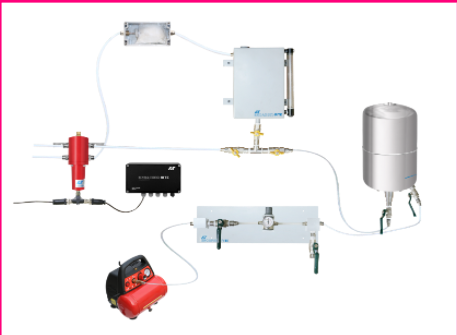

Model ESM-40S It is a liquid-level settlement system that gets embedded in the common raft foundation measuring the settlement of the portion of the raft under the reactor building. It is ideal for precision data by remote monitoring.

ESM-40S digital high precision liquid level settlement system

ESM-40S digital high precision liquid level settlement systemESM-40S digital high precision liquid level settlement system

3. Borehole extensometer:

Model EDS-70V is an electrical multipoint borehole extensometer system with vibrating wire displacement transducers for monitoring relative vertical movement. These movements are measured concerning deep and stable rock in which the deepest anchor is embedded.

EDS-70 multi-point borehole stress meter

EDS-70 multi-point borehole stress meterEDS-70 multi-point borehole stress meter

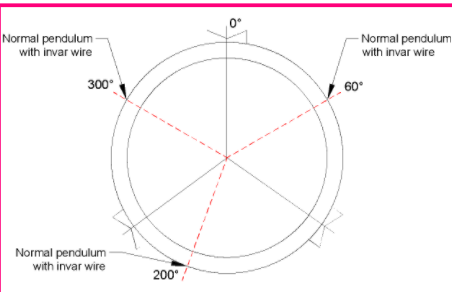

4. Plumb line:

For global deformation monitoring of the cylindrical wall of the containments, the Encardio Rite model EDS-50 normal plumb line with model EPR-01S tele-co-odometer is available to monitor relative horizontal movement in x & y planes.

Typical locations for the normal plumb lines with invar wire

Typical locations for the normal plumb lines with invar wireTypical locations for the normal plumb lines with invar wire

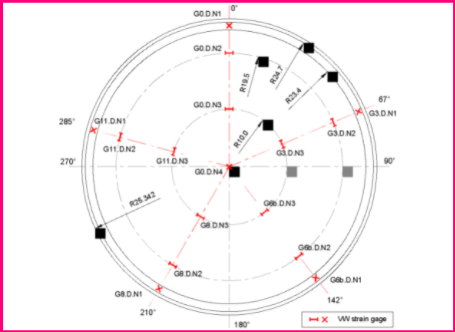

5. Strain gages:

For the measurement of local strains in the containments, dome, raft, and other structures of the plant during construction, periodic testing, and in normal operation, Encardio Rite model EDS-11V hermetically sealed vibrating wire strain gage or model EDS-21V-E extended range vibrating wire strain gage is embedded. These are placed in concrete structures to measure local strain in the inner face, outer face, and center. Based on the averaged results, and modulus of concrete elasticity, stress can be derived.

Typical location of strain gages at the common raft

Typical location of strain gages at the common raft6. Tilt meter:

For monitoring the rotational movement of the containment’s gusset at its junction with the foundation, Encardio Rite model EAN-92M tilt meters with SDI-12 output are installed at the key locations along the circumference. These tilt meters, made of stainless steel are electron beam welded with a vacuum of 1/1000 Torr inside it. These can also be installed at the ring at the junction between the dome and the cylindrical part of the containment at the key locations to measure the rotational movement.

EAN-92M digital tilt meter

EAN-92M digital tilt meter7. Load cells

To monitor the variations in the tension in the prestressing tendons used for stabilizing the foundation of the reactor, Encardio Rite offers both ELC-30S and ELC-32V. Model ELC-30S is the resistive strain gage type with 8 numbers of foil type strain gages while ELC-32V is a vibrating wire type center hole load cell with up to 6 no. vibrating wire elements. Normally, purely vertical tendons are chosen for monitoring the tension.

ELC-30S center hole load cell

ELC-30S center hole load cell8. Dataloggers:

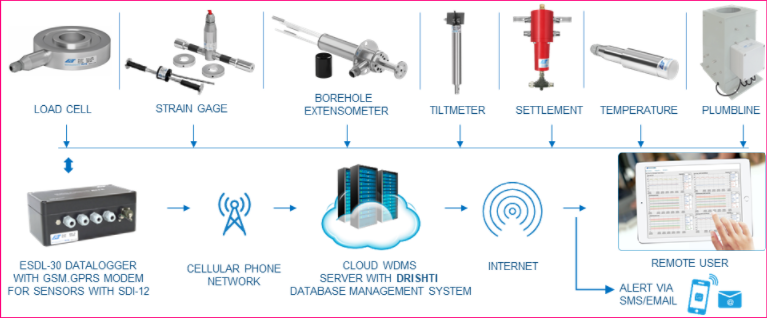

Encardio Rite provides two options to automatically log, store, and transmit data to a central server from the above-mentioned sensors:

- Model EDAS-10 based on Campbell Scientific’s CR1000X measurement and control module with GSM/GPRS modem.

- Model ESDL-30 SDI-12 data logger with an integral GSM/GPRS modem. Interface cards are available from Encardio Rite for the conversion of sensor outputs to SDI-12 digital output, where the sensors do not have an integral SDI-12 interface output.

Cloud-Based Nuclear Power Plant Monitoring Solutions

Online monitoring using the above instrumentation gives a timely warning of any impending danger. The purpose is to assist and inform the stakeholders about the continued performance of structures under gradual or sudden changes to their state. For 24X7 near real-time data access, Encardio Rite provides an online web data monitoring system (WDMS) that presents the data of the above sensors as graphs, tables, overlaid on georeferenced maps, site plans, etc.

Our in-house developed WDMS software DRISHTI retrieves the data from the field data loggers, archives the data in an SQL database, processes the data, and presents the processed data in meaningful formats to the user. A graphic like a map, ground plan, or photograph of the plant can be put on the opening screen marked with the position of the installed sensor/sensors with a square dot or hotspot near its symbol. As soon as the mouse pointer is brought over to the hot spot location, the corresponding sensor details like the sensor identification tag, last recorded sensor reading, and the values of the programmed alert levels pop up in a box. If any of the alarm levels is exceeded, the sensor location turns to a red dot. Clicking the pop-up table with the mouse brings up an associated data window where the sensor data can be seen either as a table or as a graph.

The online data provided by Encardio Rite can be assessed from just about any type of device that supports a standard web browser like a desktop, laptop, tablet, or smartphone

Structural Survey

Structural Survey

Structural Survey:

Encardio Rite partnering with the Moniterra group of affiliated companies offers a complete solution for safety monitoring that includes:

1. Laser Scanning:

Laser Scanning is an advanced method of surveying and conducting geometric documentation of buildings, architectural and archaeological monuments, engineering projects, or other construction works and objects that require a high degree of analysis, are difficult to reach or gain access to, or are not to be touched. Accuracy of up to 2-3 mm is possible using the method. Our state-of-the-art analysis software OPSIS takes very less time to process the results and makes the same available online, almost in real-time.

| Also Read OPSIS: The Smart Solution For Laser Scanning Monitoring |

2. Aerial Mapping using Unmanned Aerial Vehicles (UAV/Drone):

Nuclear power plants are huge and complex buildings that require a high degree of analysis but are difficult to reach or gain access to. Here, our advanced Unmanned Aerial Vehicles (UAV)/Drones are quite useful. Results from aerial mapping using drones provide photos & orthophotos, mesh 3D models & texture 3D models, videos – presentations, contour maps, slope maps, etc. Using UAVs/drones to video, model, and scan for cracks, erosion, corrosion, and defects in areas, that would otherwise require the inspector to use a rope/harness or erect access scaffolding, is the safer, faster and smarter choice.

Automatic Deformation Monitoring System

Automatic Deformation Monitoring System3. Automatic Deformation Monitoring System (ATS):

The 3D Deformation Monitoring System provides accurate, continuous, real-time data, which eliminates any human error/delay in manual data. The system consists of high-accuracy automated total stations (ATS) with a dedicated control box that includes a computer running special software. Our in-house developed control box manages the total station and schedules the frequency of the measurements, the addition or subtraction of monitor benchmarks, the filters of acceptance or repetition of each measurement, the atmospheric corrections in distance measurements, the calculation and repositioning of the total station, etc. The whole system can be controlled/re-configured remotely after installation at the site.

3D ATS helps in systematically tracking all the alterations that take place in the shape or dimension of a Nuclear Power Plant’s structure as a result of stress, load, aging, etc.

| Also Read: Geotechnical Data Management: Real-Time Data Monitoring System Types & Uses |

Nuclear Power Plants are considered the heart of any developed nation and it is important to keep a check on their structural health. To cater to this, the monitoring services provided by Encardio Rite are indispensable.