When constructing projects like highway embankments, bridges, dams, tanks, airport runways, buildings, etc., there is a chance of considerable settlement occurring on soft compressible soil. This happens due to the consolidation of soil due to the load application. Immediate settlement occurs in the soil upon load application, which leads to a reduction in void space, and rearrangement of the soil particles in response to the weight.

In order to avoid any expensive or problematic condition due to the settlement, it is advised to cause the consolidation at the commencement of the project, and in the shortest possible time during the construction period.

The construction on top of a soft soil foundation is usually delayed until there is an assurance that there will be no damage due to the settlement that occurs during subsequent consolidation. If the delay cannot happen, the time is reduced by surcharging and/or by the installation of vertical drains.

Soil Consolidation

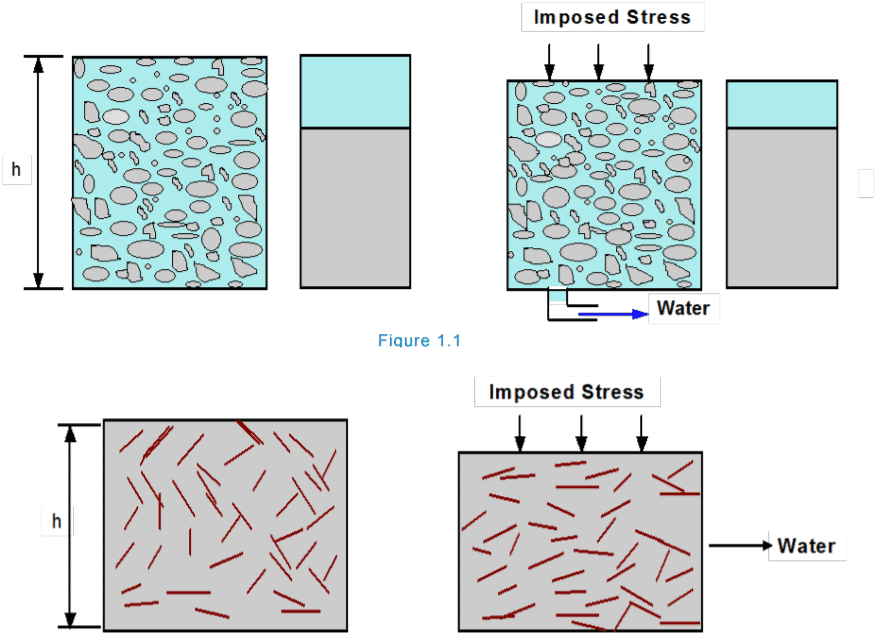

When saturated soil undergoes a steady pressure due to the weight of an embankment or overlying soil, its volume is known to decrease with time. Since the soil particles, as well as the water in the void, is compact and firm when the pressure is added, the change in the volume will occur only when the water is forced out of the voids.

As the water is flushed out, the size of the void is reduced, allowing the solid particles to come together closer. The same is shown in the picture below.

Surcharging: Surcharging or Pre-loading involves the deployment of fill material to a level higher than what is required for the original foundation or embankment. This is done in order to hasten the consolidation process. The fill material is removed once the results have been achieved.

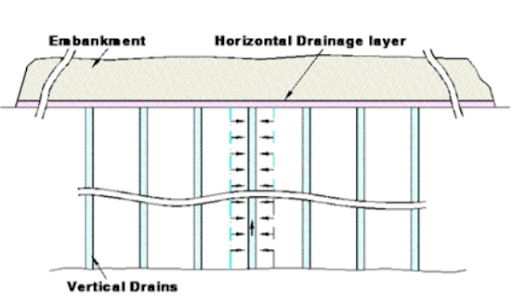

Vertical Drains (Band/wick drains): These are highly penetrable columns of high-quality flexible polypropylene measuring approximately 100 mm wide, 6mm thick, and almost 300 m in length. They are installed closely within the soil foundation and a sand blanket is placed on top of the drains. As the drain communicates with the blanket, it allows pore water pressure to dissipate quickly, thereby lowering the time taken for consolidation. Alternatively, for horizontal dissipation, prefabricated stop drains similar to vertical drains may be used instead of a sand drainage blanket.

Consolidation of Soft Foundations through Flexible Vertical Drains

This is a persistent challenge for the civil engineering community; building structures on soft compressible soils, including soft clay, peat foundations, and silt. When it comes to water-saturated, fine-grained soil, the consolidation occurs extremely slowly owing to the low permeability of the soil hindering the pore water escape from the soil voids. As the soils have poor drainage and strength properties, even with large surcharge loads, the settlement can take years as the water moves slowly and the distance to exit the soil is plenty.

To solve the issue mentioned above, prefabricated vertical drains are installed which greatly reduce the distance the water must travel to reach a free drainage path. This leads to an increase in the settlement rate. The drain spacing can be further adjusted to suit the required settlement rate.

The construction activity cannot take place without soil stabilization as the long-term settlement is usually uneven and unpredictable.

Flexible vertical drains, also known as polypropylene Vertical Drains (PVD), are employed to reduce the settlement time by quickening the consolidation process. PVDs are installed at regular spacing into the complete depth of the compressible soil layers to create a shorter horizontal drainage route. This system allows the pressurized water to flow horizontally toward the nearest drain and run smoothly through the longitudinal grooves on both sides of the vertical drain.

Usually, PVD is used in conjunction with pre-loading the surcharge with soil or vacuum pressure to further accelerate the consolidation process.

The drain includes a drain body and filter jacket.

The drain body is a perennial central plastic core that has been specifically devised to provide high discharge capacity along with high tensile and compressive strength. The core acts as a free-draining water channel.

The filter jacket surrounds the drain body and is made up of a strong, durable, non-woven polypropylene filter with high tensile strength, high permeability, and effective filtering properties. This allows easy access of pore water into the core while keeping the movement of soil particles to a minimum, and prevents piping.

With the help of the core and filter jacket, the PVD effectively provides a quick and efficient drainage system for soil improvement. PVDs are available in different core configurations and filter fabrics to suit various soil conditions and engineering practices.

Role of Instrumentation

Instrumentation for embankments of soft ground is carried on to determine the progress of consolidation, and to conclude the stability of the foundation. For instance, the instrumentation is carried on to measure the development of consolidation underneath a single-stage embankment, a surcharged embankment, or staged construction. This helps to prepare the construction schedules.

In the case of the installation of vertical drains, the instrumentations are employed to judge the effectiveness of the drain in accelerating the consolidation. Instrumentation also serves as a warning system in case of any instability, thereby allowing remedial measures that need to be executed in case of any critical situations.

If the stability of the construction is not certain or there is doubt regarding the selection of soil parameters, it may be advised to construct a test embankment and monitor the various geotechnical parameters with the assistance of various instruments. The data presented by the instrumentation plays an essential role in evaluating the performance of the test embankment.

Instrumentation for Determining Initial Site Conditions

Conventional site investigation procedures, often completed by in situ testing, are used to define the initial site conditions. However, performance monitoring instrumentation does play a role.

Taking an instance, initial groundwater pressure and fluctuations must be measured for design purposes. Piezometers can be installed prior to the start of filling which helps to define the pre-construction groundwater pressure regime, including any perched or artesian water.

In case the piezometers are installed in advance, seasonal variations can be defined. Settlement measurements may also be required to establish pre-construction settlement behaviour.

Read more: Understanding Sieve Trays in Soil Analysis

Instrumentation for Test Embankment

As we spoke about it earlier, test embankments are built to determine uncertainties in the selection of soil parameters; examine alternative construction methods, or demonstrate construction feasibility.

The instrumentation of the test embankment provides a hint of developing failure and evaluates the progress of consolidation. In addition, instrumentation also allows for a back-analysis for measuring the engineering properties of the underlying soil. In most cases, the primary parameters of interest are vertical and horizontal deformations and pore water pressure.

The quantity of instrumentation is normally greater than a prototype embankment, so maximum information is gained from the instrumentation test.

Instrumentation for Monitoring the Consolidation Process

When surcharging with vertical drains, the instrumentation is used to measure the consolidation progress. Instrumentation data allows the timeline to be measured for surcharge removal, and placement of stages and also allows an evaluation of the effectiveness of vertical drains.

Both settlement and pore water pressure measurements are addressed when evaluating the process of consolidation beneath a single-stage embankment, a surcharged embankment, or staged construction.

For instance, Piezometers are installed in the proximity of the embankment, reference piezometers are also installed remotely from the embankment, to monitor any variation in groundwater pressure that may occur from other causes.

A predictive extrapolation can be made from a plot of pore water pressure versus time because the equilibrium piezometric level corresponding to full consolidation is known to be equal to the reference value remote from the embankment.

Instrumentation for Monitoring the Stability of an Embankment

A monitoring program is expected to present forewarning of lateral instability of the embankment, thereby, allowing corrective measures to be performed before critical situations arise. The remedial measures include a waiting period which allows the foundation material to increase in strength as pore water pressures dissipate, and/or the construction of stabilizing berms or the removal of some fill.

In case the monitoring program is expected to provide an indication of incipient failure, horizontal deformation measurements will provide the most direct data. Encardio Rite Model EAN-20 Inclinometer system is the most essential tool, enhanced with surface deformation monitoring by surveying methods.

However, measurement of pore water pressure often gives the first indication of failure conditions developing than can be derived from deformation data. To be certain of having measurements in the zones of initial yielding, a relatively large number of piezometers may be required.

This brings us to the end of the article on Soil Consolidation. Hope this was helpful and informative. For more such articles, keep watching this space.