We all use temperature sensors in our daily lives, be it in the form of thermometers, domestic water heaters, microwaves, or refrigerators. Usually, temperature sensors have a wide range of applications, the geotechnical monitoring field, being one of them.

Temperature sensors are designed to keep a regular check on concrete structures, bridges, railway tracks, soil, etc.

Here we are going to tell you what is a temperature sensor, how it works, where is it used, and what are its different types.

What are the temperature sensors?

A temperature sensor is a device, typically, a thermocouple or resistance temperature detector, that provides temperature measurement in a readable form through an electrical signal.

A thermometer is the most basic form of a temperature meter that is used to measure the degree of hotness and coolness.

Temperature meters are used in the geotechnical field to monitor concrete, structures, soil, water, bridges, etc. for structural changes in due to seasonal variations.

A thermocouple (T/C) is made from two dissimilar metals that generate an electrical voltage in direct proportion to the change in temperature. An RTD (Resistance Temperature Detector) is a variable resistor that changes its electrical resistance in direct proportion to the change in the temperature in a precise, repeatable, and nearly linear manner.

What do temperature sensors do?

A temperature sensor is a device that is designed to measure the degree of hotness or coolness in an object. The working of a temperature meter depends upon the voltage across the diode. The temperature change is directly proportional to the diode’s resistance. The cooler the temperature, the lesser will be the resistance, and vice-versa.

The resistance across the diode is measured and converted into readable units of temperature (Fahrenheit, Celsius, Centigrade, etc.) and, displayed in numeric form over readout units. In the geotechnical monitoring field, these temperature sensors are used to measure the internal temperature of structures like bridges, dams, buildings, power plants, etc.

What are the functions of a temperature sensor?

Well, there are many types of temperature sensors, but, the most common way to categorize them is based on the mode of connection which includes, contact and non-contact temperature sensors.

Contact sensors include thermocouples and thermistors because they are in direct contact with the object they are to measure. Whereas, the non-contact temperature sensors measure the thermal radiation released by the heat source. Such temperature meters are often used in hazardous environments like nuclear power plants or thermal power plants.

In geotechnical monitoring, temperature sensors measure the heat of hydration in mass concrete structures. They can also be used to monitor the migration of groundwater or seepage. One of the most common areas where they are used is while curing the concrete because it has to be relatively warm in order to set and cure properly. The seasonal variations cause structural expansion or contraction thereby, changing its overall volume.

How does a temperature sensor work?

The basic principle of working the temperature sensors is the voltage across the diode terminals. If the voltage increases, the temperature also rises, followed by a voltage drop between the transistor terminals of the base and emitter in a diode.

Besides this, Encardio Rite has a vibrating wire temperature sensor that works on the principle of stress change due to temperature change.

The vibrating wire temperature meter is designed on the principle that dissimilar metals have a different linear coefficient of expansion with temperature variation.

It primarily consists of a magnetic, high tensile strength stretched wire, the two ends of which are fixed to any dissimilar metal in a manner that any change in temperature directly affects the tension in the wire and, thus, its natural frequency of vibration.

The dissimilar metal, in the case of the Encardio Rite temperature meter, is aluminum (Aluminum has a larger coefficient of thermal expansion than steel.) As the temperature signal is converted into frequency, the same read-out unit which is used for other vibrating wire sensors can also be used for monitoring temperature also.

The change in temperature is sensed by the specially built Encardio Rite vibrating wire sensor and is converted to an electrical signal which is transmitted as a frequency to the read-out unit.

The frequency, which is proportional to the temperature and in turn to the tension ‘σ’ in the wire, can be determined as follows:

f = 1/2 [σg/ρ] / 2l Hz

Where:

σ = tension of the wire

g = acceleration due to gravity

ρ = density of the wire

l = length of wire

What are the different types of temperature sensors?

Temperature sensors are available in various types, shapes, and sizes. The two main types of temperature sensors are:

Contact Type Temperature Sensors: There are a few temperature meters that measure the degree of hotness or coolness in an object by being in direct contact with it. Such temperature sensors fall under the category of contact type. They can be used to detect solids, liquids, or gases over a wide range of temperatures.

Non-Contact Type Temperature Sensors: These types of temperature meters are not in direct contact with the object rather, they measure the degree of hotness or coolness through the radiation emitted by the heat source.

The contact and non-contact temperature sensors are further divided into:

1. Thermostats

A thermostat is a contact-type temperature sensor consisting of a bi-metallic strip made up of two dissimilar metals such as aluminum, copper, nickel, or tungsten.

The difference in the coefficient of linear expansion of both metals causes them to produce a mechanical bending movement when it’s subjected to heat.

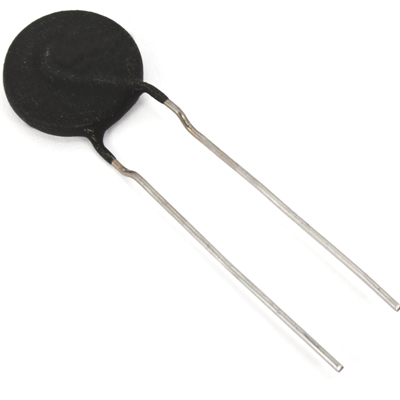

Thermistors

Thermistors or thermally sensitive resistors are the ones that change their physical appearance when subjected to a change in temperature. The thermistors are made up of ceramic material such as oxides of nickel, manganese, or cobalt coated in glass which allows them to deform easily.

Most of the thermistors have a negative temperature coefficient (NTC) which means their resistance decreases with an increase in the temperature. But, there are a few thermistors that have a positive temperature coefficient (PTC), and, their resistance increases with a rise in the temperature.

Resistive Temperature Detectors (RTD)

RTDs are precise temperature sensors that are made up of high-purity conducting metals such as platinum, copper, or nickel wound into a coil. The electrical resistance of an RTD changes similar to that of a thermistor.

Thermocouples

One of the most common temperature sensors includes thermocouples because of their wide temperature operating range, reliability, accuracy, simplicity, and sensitivity.

A thermocouple usually consists of two junctions of dissimilar metals, such as copper and constantan that are welded or crimped together. One of these junctions, known as the Cold junction, is kept at a specific temperature while the other one is the measuring junction, known as the Hot junction.

On being subjected to temperature, a voltage drop is developed across the junction.

Negative Temperature Coefficient (NTC) Thermistor

A thermistor is basically a sensitive temperature sensor that reacts precisely to even minute temperature changes. It provides a huge resistance at very low temperatures. This means, that as soon as the temperature starts increasing, the resistance starts dropping quickly.

Due to the large resistance change per degree Celsius, even a small temperature change is displayed accurately by the Negative Temperature Coefficient (NTC) Thermistor. Because of this exponential working principle, it requires linearization. They usually work in the range of -50 to 250 °C.

Semiconductor-Based Sensors

A semiconductor-based temperature sensor works with dual integrated circuits (ICs). They contain two similar diodes with temperature-sensitive voltage and current characteristics to measure the temperature changes effectively.

However, they give a linear output but, are less accurate at 1 °C to 5 °C. They also exhibit the slowest responsiveness (5 s to 60 s) across the narrowest temperature range (-70 °C to 150 °C).

Model ETT-10V Vibrating Wire Temperature Sensor

The Encardio Rite Model ETT-10V vibrating wire temperature meter is used for the measurement of internal temperature in concrete structures or water. It has a resolution of better than 0.1°C and works similarly to that of Thermocouple Temperature Sensors. It also has a high-temperature range from -20° to 80° C.

Specifications of ETT-10V Vibrating Wire Temperature Meter

| Sensor type | Pt 100 |

| Range | -20o to 80o C |

| Accuracy | ± 0.5 % fs standard; ± 0.1 % fs optional |

| Dimension (Φ x L) | 34 x 168 mm |

Model ETT-10TH Resistance Thermistor Probe

The Encardio Rite Model ETT-10TH resistance temperature probe is a low-mass waterproof temperature probe for measurement of temperature between –20 to 80°C. Due to its low thermal mass, it has a fast response time.

Model ETT-10TH resistance temperature probe is specially designed for the measurement of surface temperatures of steel & measurement of the surface temperature of concrete structures. ETT-10TH can be embedded in concrete for measurement of bulk temperature inside the concrete and can even work submerged underwater.

ETT-10TH resistance temperature probes are fully interchangeable. The temperature readings will not differ by more than 1°C over the specified working temperature range. This allows a single indicator to be used with any ETT-10TH probe without recalibration.

Encardio Rite’s model EDI-51V vibrating wire indicator when used with ETT-10TH directly shows the probe temperature in degrees Celsius.

How Does Model ETT-10TH Resistance Thermistor Probe Works?

ETT-10TH temperature probe consists of a resistance-temperature curve matched thermistor epoxy encapsulated in copper tubing for faster thermal response and environmental protection. The tube is flattened at the tip so that it can be fixed to any reasonably flat metal or concrete surface for measurement of surface temperature.

The flat tip of the probe can be fixed to most surfaces with the help of easily available two-part epoxy adhesives. If desired, the probe can also be bolted down to the surface of the structure.

The temperature probe is provided with a four-core cable used as a standard in all Encardio Rite vibrating wire strain gauges. The white and green colored wires are used for the thermistor similar to the other Encardio Rite vibrating wire sensors.

The pair of red and black wires is left unused. The uniform color scheme across different sensors makes it easier to have error-free connections with a data logger terminal.

Specifications of Model ETT-10TH

| Sensor Type | R-T curve matched NTC thermistor, equivalent to YSI 44005 |

| Range | -20o to 80oC |

| Accuracy | 1oC |

| Body material | Tin plated copper |

| Cable | 4 core PVC sheathed |

Model ETT-10PT RTD Temperature Probe

The ETT-10PT RTD (Resistance Temperature Detector) temperature probe consists of a ceramic resistance element (Pt. 100) with DIN IEC 751 (former DIN 43760) European curve calibration. The resistance element is housed in a closed-end robust stainless steel tubing which protects the element against moisture.

How Does Model ETT-10PT RTD Temperature Probe Work?

The resistance temperature probe works on the principle that sensor resistance is a function of the sensed temperature. The Platinum RTD has very good accuracy, linearity, stability and repeatability.

The model ETT-10PT resistance temperature probe is provided with a three-core shielded cable. The red wire provides one connection and the two black wires together provide the other. Thus, compensation is achieved for lead resistance and temperature change in lead resistance. The resistance temperature sensor readings can be read easily using a digital RTD temperature indicator.

Specifications of Model ETT-10PT RTD Probe

| Sensor type | Pt 100 |

| Range | -20o to 80o C |

| Accuracy | ± (0.3 + 0.005*t)o C |

| Calibration | DIN IEC 751 |

| Curve (European) | 0.00385 Ohms/Ohm/oC |

| Dimension (Φ x L) | 8 x 135 mm |

| Cable | 3 core shielded |

Encardio Rite Thermocouple

The Encardio Rite offers a T-type thermocouple (Copper-Constantan) for the measurement of internal temperature in concrete structures. It consists of two dissimilar metals, joined together at one end. When the junction of the two metals is heated or cooled a voltage is produced that can be correlated back to the temperature.

Thermocouple measurement consists of a thermocouple wire with two dissimilar conductors (Copper-Constantan) joined at one end to form a hot junction. This end is sealed against corrosion and placed at the required locations for temperature measurement.

The other end of the thermocouple wire is connected to a suitable thermocouple connector to form a cold junction. The thermocouple readout displays a direct reading of the temperature at the installed location and automatically compensates for the temperature at the cold junction.

Specifications of Encardio Rite Thermocouple

| Wire Type | T-Copper-Constantan |

| Wire Insulation | PFA TeflonC |

| Hot junction Temperature | Up to 260oC (Max) |

| Connector Type Miniature | Glass-filled Nylon |

| Service temperature | -20o to to 100oC |

| Cold Junction Temperature | Ambient |

Where is the temperature sensor used?

The temperature sensor’s applications include:

- The temperature sensors are used for verifying design assumptions that will promote safer and more economical design and construction.

- They are used to measure the temperature rise during the process of curing concrete.

- They can measure rock temperatures near liquid gas storage tanks and ground freezing operations.

- Temperature sensors can also measure water temperatures in reservoirs and boreholes.

- It can be used to interpret temperature-related stress and volume changes in dams.

- They can also be used to study the temperature effect on other installed instruments.

Advantages Of Encardio Rite’s Temperature Sensors

- The Encardio Rite temperature sensor is precise, low-cost, and extremely reliable.

- They are suitable for both surface mount and embedded applications.

- The low thermal mass results in faster response time.

- The vibrating wire temperature sensor is fully interchangeable; one indicator can read all sensors.

- It has a weather-proof body rated IP-68.

- They come with indicators that are readily available for direct temperature display.

- The temperature probes have excellent linearity and hysteresis.

- The vibrating wire technology assures long-term stability and quick and easy readout.

- The sensors are hermetically sealed by electron beam welding with a vacuum of around 1/1000 Torr inside it.

- They are suitable for remote reading, scanning as well as data logging.

FAQs

Q1. What is the difference between the temperature sensor and the temperature transmitter?

Ans: A temperature sensor is an instrument used to measure the degree of hotness or coolness of an object whereas, a temperature transmitter is a device that is interfaced with a temperature sensor to transmit the signals to a remote location for monitoring and control purposes.

This means a thermocouple, RTD, or thermistor is connected to a data logger to get the data at any remote location.

Q2. How Is Temperature Measured In A Concrete Dam?

Ans: Except for the procedure adopted during construction, the greatest single factor in causing stress in mass concrete is due to the temperature change. For analyzing the development of thermal stress and for control of artificial cooling, it is, therefore, necessary to monitor the temperature variation of concrete during construction.

For this, the temperature should be accurately measured at many points in the structure, in the water, and in the air. A sufficient number of sensors should be embedded to get a correct picture of temperature distribution at various points in the structure.

In a large concrete dam, a typical scheme would be to place a temperature probe every 15 – 20 m along the cross-section and every 10 m along the elevation. For smaller dams, the spacing may be reduced. A temperature probe placed in the upstream face of a dam evaluates the reservoir temperature as it varies throughout the year.

This is much easier than dropping a thermometer in the reservoir every now and then to take observations. During the operation of a concrete dam, diurnal and seasonal changes in the environment, play havoc as far as the development of thermal stresses in the structure is concerned. The effect is more pronounced on the downstream side. A few temperature sensors should be placed near and in the downstream face of the concrete dam to evaluate the rapid daily and weekly fluctuation in temperature.

Q3. Which Is The Most Accurate Temperature Sensor?

Ans: An RTD is the most accurate temperature sensor. The Platinum RTD has very good accuracy, linearity, stability, and repeatability as compared to thermocouples or thermistors.

Q4. What is a thermocouple?

Ans: A thermocouple is a type of temperature sensor that is used to measure the internal temperature of an object.

There are three laws for thermocouples as stated below:

1. Law of homogenous material: If all the wires and the thermocouple are made of the same material, temperature changes in the wiring do not affect the output voltage. Hence, wires made up of distinct materials are needed.

2. Law of intermediate materials: The sum of all the thermoelectric forces in a circuit with a number of dissimilar materials at a uniform temperature is zero. This implies that if a third material is added at the same temperature, no net voltage is generated by the new material.

3. Law of successive or intermediate temperatures: If two dissimilar homogeneous materials produce thermal emf1 when the junctions are at T1 and T2 and produce thermal emf2 when the junctions are at T2 and T3, the emf generated when the junctions are at T1 and T3 will be emf1 + emf2

Q5. How do you test a temperature sensor?

Ans: At Encardio Rite, we have specialized temperature testing chambers (with already known temperature and temperature control systems) to test the accuracy and quality of our temperature sensors.

This was all about the temperature sensors, their different types, applications, uses, as well as, working principles. Do let us know your queries in the comments section below.