Encardio Rite single-point borehole extensometer is a geotechnical instrument devised to assist civil engineers and geologists in the measurement of deformation of rock mass and adjacent or surrounding soil. Coupled with an anchor bolt load cell and tape extensometer, it makes for an essential piece of equipment for the complete monitoring of foundations, slopes & embankments and for studying the behaviour of rock around underground cavities, tunnels, and mines.

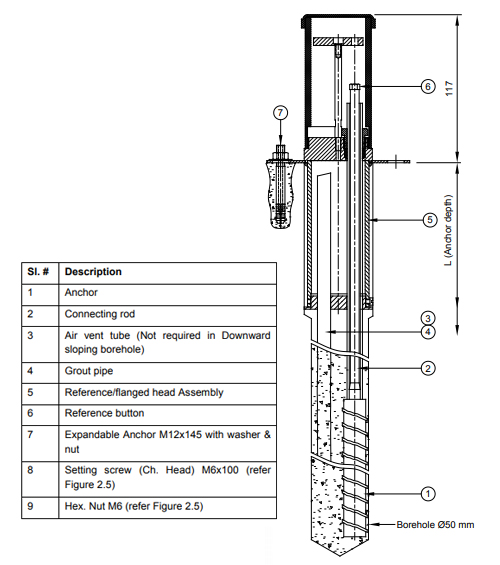

Encardio Rite Model EDS-64UD borehole extensometer is used for upward or downward-sloping holes working with stainless steel or fiberglass connecting rods. It is capable of being installed in a borehole of φ 50 mm with a diameter at the mouth of the borehole increased to 62 mm up to a depth of 200 mm.

Let’s have a look at the application of borehole extensometer.

Borehole Extensometer- Application

- To understand the behaviour of the roof, wall of mine, underground cavity, or tunnel during excavation.

- To analyze the effectiveness of the roof/wall support system of a mine, underground cavity, or tunnel.

- To determine and monitor the movements in slopes and foundations that occur due to excavation of underground cavities or heavy construction of structures like concrete, rock-fill, masonry, or earth dams over the foundation.

Single Point Borehole Extensometer- Introduction

As discussed, a borehole extensometer determines the displacement taking place in a borehole with reference to time. Once installed, the single-point borehole extensometer successfully measures the distance between the anchor (1) and the reference plate (5.8) and monitors it with time.

Assuming that the anchor is in stable ground, any change in the spacing of the anchor is understood as a movement of sidewall or slope, sag of roof bed, settlement of foundation, etc.

Single Point Borehole Extensometer- Operating Principle

Encardio Rite Model EDS-64U/D is a mechanical borehole extensometer in which a single anchor is positioned in a borehole. The relative displacement is then measured over time with respect to a reference plate.

The model is especially efficient in measuring the displacement when it comes to boreholes with easy access to the mouth. It becomes economical and reliable to use the single-point extensometer rather than any other.

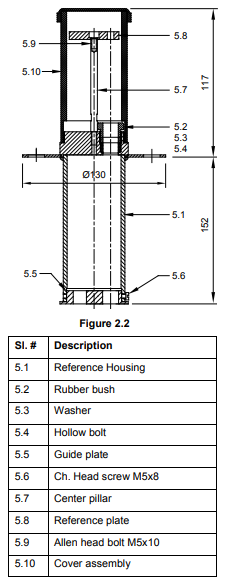

A micrometer depth gauge is used to capture the displacement reading by measuring the depth of the reference button at the near end of the connecting rod from a reference plate.

A borehole extensometer is comprised of three major elements:

- Reference head assembly

- Stainless steel/Fiberglass assembly

- Anchor

Single Point Borehole Extensometer – Reference Head Assembly

The image below explains the parts and the reference head assembly. It is installed in a borehole of φ 50 mm. The diameter of the mouth of the borehole is then expanded to 2 mm up to a depth of 200 mm. The flange consists of four 15 mm diameter mounting holes at a PCD of 105 mm.

Single Point Borehole Extensometer -Stainless steel/Fibreglass rod assembly

The rod assembly consists of a stainless steel/fiberglass rod of specified length shielded inside an outer PVC tubing or continuous nylon tube. The rod is equipped with two ends connected, with one end having a male thread that goes into the anchor. The other end fitted with a female thread is reserved for the reference button.

One end of the PVC/nylon tube is tightly sealed to the anchor to prevent any leaking of the grout. The other end of the PVC/nylon tube is firmly seated in the reference head assembly.

Make sure that the reference head assembly is firmly sealed especially while installing in upwards to horizontally slanting holes to prevent the grout from leaking and entering the reference head assembly.

Even while grouting, the stainless steel/fiberglass rod and reference button are free to move inside the outer tube casing.

NOTE: Fibreglass rods are more compatible in vertical upward holes as compared to downward holes. When installed in a vertically upwards holed, the rod remains in tension whereas in a downward holed, compression may result in sagging or buckling.

The longer the extensometer, the greater may be the sagging or buckling. Similarly, the shorter the extensometer, the better the accuracy of the measured displacement. Therefore, in deeper boreholes, it is advised to use stainless steel rods owing to their rigid characteristic.

The design Engineer should make a note of the field condition and measurement accuracy before deciding the type of connecting rod.

The actual performance of rods is determined by site conditions and it is recommended to conduct some field tests to arrive at a proper conclusion.

Single Point Borehole Extensometer- Anchor

Another very important element of a borehole extensometer is the Anchor.

Encardio Rite groutable anchor is usually φ 20 mm x 500 mm long and is employed for hard rocks. The anchor is placed inside the borehole with a connecting rod of the required length and is set in position with the help of cement grout. The connecting rod remains away from the cement grout as it is placed in a PVC/nylon tubing and therefore, can move freely.

Groutable anchors can also be installed in vertical boreholes or holes inclined upwards. However, special precautions must be taken to block the grout from flowing out of the borehole.

The reinforced bar groutable anchor of diameter 20 mm x 500 mm long is usually used in rock. In the case where the groutable anchor has to be installed in a deep borehole, it becomes important to grout in stages. This may require some modification in the design.

NOTE: Encardio Rite uses the convention that the depth of the anchor is calculated as the distance from the mouth of the hole to the near end of the anchor.