Geotechnical instrumentation and monitoring is a vast field that encompasses several instruments such as piezometers, load cells, strain gauges, tiltmeters, survey markers, etc.

An integral part of Geotechnical Monitoring and instrumentation, pressure cells find their application in multiple arenas. They are also available in different shapes, sizes, and types, allowing them a wide range of implementation.

If you’re curious about what is a pressure cell, its type, and other technical details, keep reading to know more!

What is a pressure cell?

What is a pressure cell?

What is a Pressure Cell?

Before we move forward with the technicalities, let’s first understand the pressure cell definition.

A pressure cell is a type of sensor that converts stress or pressure into a measurable and readable electrical unit. The pressure cell is fundamentally used to measure total stress in various geotechnical construction fields.

The vibrating wire pressure cells are based on vibrating wire technology. Encardio Rite currently deals with six different types of pressure cells.

Let’s take a closer look at how pressure cells are employed in the geotechnical field.

How is a Pressure Cell used in the geotechnical field?

The rock/soil formation is completely dependent on the rock/soil type, stress history, shear, and normal stress levels, boundary and drainage conditions, and several environmental effects. The precise assessment of stress and changes that occur in foundation soil/rock formations is of great importance for safe engineering design.

While constructing large civil engineering projects like tall buildings, dams, underground tunnels, etc., measurement of stress plays a vital role.

The types of stress can be categorized as:

- Measurement of total stress at a point within a soil mass/foundation rock/concrete structure.

- Measurement of contact stress against the face of a structural element.

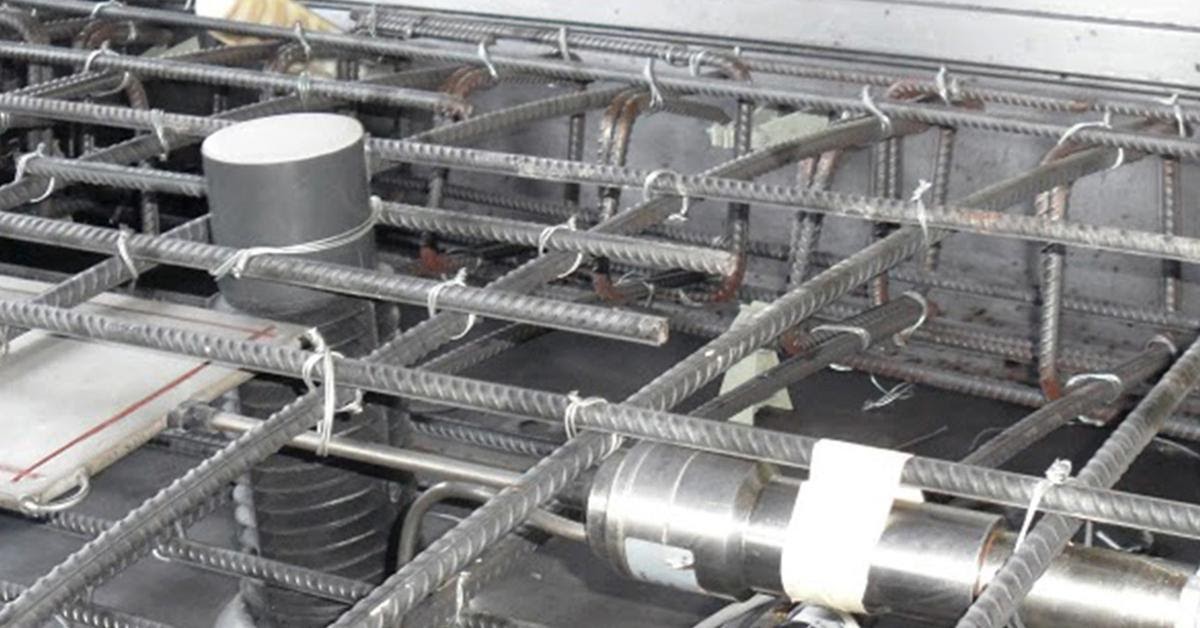

Pressure cells installed in the Pir Panjal tunnel

Pressure cells installed in the Pir Panjal tunnelFigure 1: Pressure cells installed in Pir Panjal tunnel

The vibrating wire pressure cells are much more reliable and faster than all the other types as they are capable of taking readings electrically as the frequency output is almost immune to external noise. The cable from the pressure sensor is connected to the readout unit or data logger and is protected against any possible damage during construction to give all-around reliable data.

Out of all the available pressure cells, the Encardio Rite vibrating wire pressure cell (or stress cell) is considered rugged, reliable, and accurate. Also, it can tolerate wet wiring conditions common in geotechnical applications and is capable of transmission of signals over long distances.

The applications of pressure cells (stress cells) are as below-

- Pressure cells are designed to monitor radial and tangential stresses in shotcrete tunnel linings, underground excavations, unlined caverns, and foundations.

- Pressure Cells are used to assess the adequacy of the shotcrete lining.

- They are used to monitor mine backfill.

- To measure the orientation and magnitude of total pressure and stress distribution within dam embankments and the interface of soil and concrete.

- To determine contact pressure on retaining and diaphragm walls, piers, and abutments.

What is the Working Principle of a Pressure Cell?

A pressure sensor converts the stress or applied pressure into measurable electrical output.

Pressure can be defined as the applied force per unit area that a fluid exerts on its surroundings. The pressure is given by:

Pressure (P) = Force (F)/Area (A)

The pressure transducers consist of a sensor with a constant area and respond to the force applied by fluid pressure. The force applied tends to deflect the diaphragm inside the pressure cell. The deflection of the diaphragm is calculated and converted into readable electrical output by the data loggers or readout units.

What Are the Different Types of Pressure Cells?

Encardio Rite has different Models of Pressure Cells which include:

- Model EPS-30V-C Concrete Pressure Cell

- Model EPS-30V-I Soil and Rock-Concrete Interface Pressure Cell

- Model EPS-30V-J Jack Out Pressure Cell

- Model EPS-30V-S Earth Pressure Cell

- Model ESC-30V Shotcrete-Concrete Stress Cell

1. Model EPS-30V-Series Earth and Concrete Pressure Cells: The Encardio Rite Earth and concrete pressure cell primarily consists of a flexible and circular flat capsule constructed from two stainless steel discs. These stainless steel discs are welded around the periphery and connected to a specially designed Encardio Rite pressure transducer incorporating the latest vibrating wire technology.

The vibrating wire technology allows for remote and digital readout. The pressure cell has inherently high sensitivity and it is not necessary to produce a large strain on the area being monitored for the measurement of stress. Encardio Rite offers three types of Model EPS-30V-Series pressure cells:

2. Model EPS-30V-S Earth Pressure Cell: Suffix ‘S’: for use in soil, earth, or rock fills

Model EPS-30V-S Earth Pressure Cell

Model EPS-30V-S Earth Pressure CellThe Model EPS-30V-S Earth Pressure Cell is 200 mm Φ x 7 mm thick. It consists of two stainless steel diaphragm plates welded around the periphery. The pressure pad is connected to the vibrating wire pressure sensor through a 6 mm diameter x 165 mm long stainless tube. The narrow cavity inside the pressure pad and the tube is filled with fluid.

3. Model EPS-30V-C Concrete Pressure Cell: Suffix ‘C’: for use in concrete

Model EPS-30V-C Concrete Pressure Cell

Model EPS-30V-C Concrete Pressure CellThe Model EPS-30V-C Concrete pressure capsule is similar to EPS-30V-S. For applications in which the concrete pressure cell is embedded in concrete, a 600 mm long pinch tube is welded to the transducer.

Once the concrete is cured, due to cooling the shrinkage of the capsule is created which creates a gap between the concrete and the cell which prevents the transmission of pressure on the cell. Thus to fill the gap, a pinch tube is squeezed to push the fluid to inflate the cell and develop a positive pressure on it.

Here’s a video for more information on Model EPS-30V-C Concrete Pressure Cell:

4. Model EPS-30V-I Soil and Rock-Concrete Interface Pressure Cell: Suffix ‘I’: for use at concrete and soil interface

Model EPS-30V-I

Model EPS-30V-IThe Model EPS-30V-I Soil and Rock-Concrete Interface Pressure Cell is similar to the above except that it is 200 mm Φ x 10 mm thick and the diaphragm on one of the sides is rigid.

Watch the video below to learn more about Model EPS-30V-I Soil and rock concrete interface pressure cell.

Working Principle of Model EPS-30V-Series Earth and Concrete Pressure Cells

The pressure applied by the earth or concrete acts on the cell and is transmitted through the fluid in the stress capsule to an integral diaphragm, which forms part of the pressure transducer.

The change in pressure causes the diaphragm to deflect, thus altering the tension of the wire. Any change in the tension of the wire affects its resonant frequency of vibration, which is related to the pressure acting on the cell.

The resonant frequency with which the wire vibrates can be accurately measured. Encardio Rite Model EDI-51V VW readout unit will be used for manual reading, ESDL-30 or EDAS-10 data acquisition systems are available for online monitoring pressure at the site.

Data can also be transmitted over long distances to remote data acquisition system Model ESDL-30 or EDAS-10.

Read More: Strain Gauge: Principle, Types, Features and Applications

Specifications of Model EPS-30V-Series Earth and Concrete Pressure Cells

The pressure cell essentially consists of a flat circular capsule and a pressure transducer connected by a 6 mm Φ x 165 mm long stainless steel tube. To understand the pressure transducer working principle, you can check out our blogs.

Range (MPa) | 0.5, 1.0, 2.0, 3.5, 5.0, 10.0, specify |

Accuracy of VW pressure Transducer | ± 0.5 % fs normal ± 0.1 % is optional |

Over range limit | 150 % of range |

Temperature limit | -20 to 80°C |

Operational thermistor | YSI 44005 or equivalent |

Required accessories | Portable read-out unit/logger |

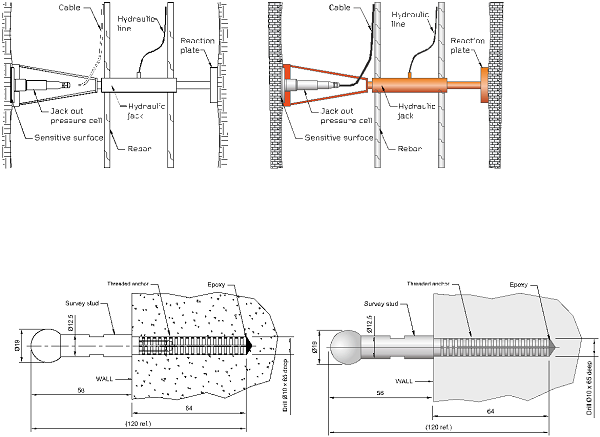

Model EPS-30V-J Jack Out Pressure Cell

Model EPS-30V-J Jack Out Pressure Cell

Model EPS-30V-J Jack Out Pressure CellThe total stress measurement in the soil can be categorized as follows:

- Measurement within a soil mass.

- Measurement at the face of a structural element.

Encardio Rite Jack-Out Pressure Cell falls in the latter category. The name of the cell is derived from the use of a hydraulic jack during installation by activating it to keep the cell in position while the concrete is poured in.

Encardio Rite Model EPS-30V-J Jack-Out Pressure Cell is used for monitoring changes in stress base slabs and diaphragm/slurry walls etc. It is extensively used:

- Where concrete is cast directly against soil, i.e. cast in place structures.

- As a safety measure to monitor if the earth pressure is more than the designed limits.

- For verification of design assumptions and to provide data and information for safer and more economical future designs.

The Model EPS-30V-J Jack-Out Pressure Cell is designed to measure the total stress i.e. the effective stress due to the soil together with the pore water pressure in the voids between soil grains. It is suitable for measuring static or slowly varying stresses only.

Working Principle of Model EPS-30V-J Jack Out Pressure Cell

The Jack-Out Total Pressure Cell consists of a circular flat capsule, constructed from two stainless steel discs welded around the periphery. One of the discs is a thin flexible diaphragm of around 3 mm thickness. It is the active face and is installed flush with the soil.

The other disc is a thick rigid plate of around 12 mm thickness. It is the inactive face and is installed on the concrete side through another thick support plate. To prevent uneven stress on the cell, the jack acts on the support plate, rather than directly on the cell.

Care should be taken to have the sensitive surface of the cell completely flush out with the soil at the concrete/soil interface. This is achieved by activating a hydraulic jack to keep the cell in position while the concrete is poured in.

The hydraulic pressure on the jack is maintained somewhat higher than the stress generated by the freshly poured-in concrete at the level at which the jack-out pressure cell is mounted. This will prevent the poured concrete from seeping into the soil and cell interface.

The jack-out pressure cell is a robust sensor designed to effectively function under the condition of rough handling and concreting.

Construction of Model EPS-30V-J Jack out Pressure Cell

Construction of Model EPS-30V-J

Construction of Model EPS-30V-JThe Jackout Pressure cell is 14 mm thick and has a diameter of either 200 mm or 125 mm. It is constructed from two stainless steel plates welded together around the periphery to leave a narrow space between them. This space is filled with de-aired fluid and connected hydraulically to a pressure sensor.

The sensor has an all-welded construction such that the space confining the hydraulic fluid is entirely metal, not requiring ‘O’ rings that tend to trap air and reduce cell stiffness. The hydraulic fluid is de-aired which materially improves fluid stiffness and performance of the cell.

The pressure transducer is made of stainless steel construction with a size of 42 mm Ф x 176 mm long. It incorporates the latest vibrating wire technology and has an inherently high sensitivity. The transducer converts the fluid pressure into an electrical signal in the form of frequency, which can be accurately measured by a model EDI-51V vibrating wire readout unit or any other conventional vibrating wire readout unit.

The signal can also be transmitted over long distances to a remote automatic data acquisition system like Encardio Rite Model EDAS-10.

Specification of Model EPS-30V-J Jack out Pressure Cell

Range (MPa) | 0.5, 1.0, 2.0, 3.5, 5.0, specify |

Accuracy (of pressure transducer) | ± 0.5 % fs with our EDI-51V digital readout. ± 0.1 % is available on request |

Temperature limit: Operational | -20 to 80°C |

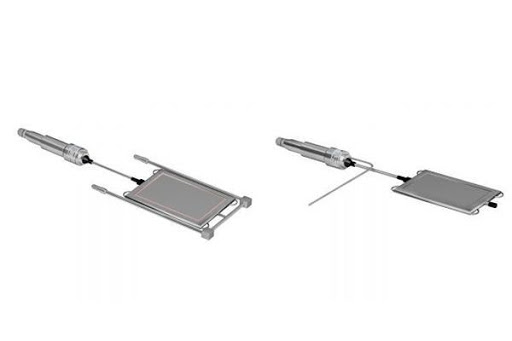

Model ESC-30V Shotcrete-Concrete Stress Cell

ESC-30V & ESC-30V-R Shotcrete-Concrete Stress Cell

ESC-30V & ESC-30V-R Shotcrete-Concrete Stress CellFigure 2: ESC-30V & ESC-30V-R Shotcrete-Concrete Stress Cell

The ‘New Austrian Tunneling Method’, or N.A.T.M., calls for the support of a tunnel by the rapid application of shotcrete to the freshly exposed ground.

The theory behind this method of support, particularly useful in weaker grounds, is that if the inherent strength of the ground can be preserved, it will be almost self-supporting and will require much less artificial support in the form of concrete or steel. Proper evaluation of total stress may help in:

The adequacy of the shotcrete lining indicates the need for perhaps more or less shotcrete to maintain stability.

Verifying design assumptions that will promote safer and more economical design and construction.

NATM being carried out

NATM being carried outFigure 3: NATM being carried out

Shotcrete concrete stress cells are designed for the measurement of radial and tangential stresses in shotcrete tunnel linings. They are often used in conjunction with the borehole extensometer to measure:

- The performance of the lining

- To determine whether the lining is thick enough to maintain stability.

Working Principle of Model ESC-30V Shotcrete-Concrete Stress Cell:

The Encardio Rite N.A.T.M. style shotcrete concrete stress cells consist of a flat rectangular capsule and a pressure transducer connected by a 6 mm Ф x 165 mm long stainless steel tube. The rigidity of the cell exceeds 50,000 MPa and ensures it will respond immediately and accurately to the onset of increasing concrete stresses.

(a) Fluid-filled Pressure Cells: The Encardio Rite Model ESC-30V shotcrete-concrete cells consist of two rectangular plates welded around the edge. The cavity inside the pressure pad is filled with de-aired fluid.

(b) Vibrating Wire Transducer: The stainless steel pressure transducer is 42 mm x 190 mm long. It incorporates a vibrating wire, coil magnet assembly, and cable joint housing. Each pressure cell is individually temperature compensated to 0.03%/°C.

(c) Lugs: Lugs are provided at the corners of the rectangular plates to facilitate holding the cell in a plane while the shotcrete is applied.

(d) Pinch Tube: One end of a 600 mm long pinch tube filled with fluid is welded to the pressure cell. The other end is capped by welding. During concrete lining, temperatures very often rise and cause the capsule to expand in the still-green concrete.

On cooling, the capsule contracts, which, if allowed to remain, would prevent the transmission of pressures from the concrete to the cell. The purpose of the pinch tube is to inflate the capsule after the concrete around it has fully cured and has cooled off to the ambient temperature.

A set of pliers is used to squeeze the fluid into the pinch tube. The fluid is forced out of the tube into the capsule which expands until the gap is eliminated.

Construction of Model ESC-30V Shotcrete-Concrete Stress Cell

An increase in stress in the concrete causes a vibrating wire pressure cell and is converted to an electrical signal which is transmitted as a frequency signal to read out the unit.

The pressure cell consists of a magnetic, high tensile strength stretched wire, one end of which is anchored and the other end fixed to a diaphragm which deflects in some proportion to the applied pressure.

The pressure cell working is a very simple matter.

Any deflection of the diaphragm changes the tension in the wire, thus affecting the resonant frequency of the vibrating wire. The resonant frequency with which the wire vibrates can be accurately measured by the vibrating wire readout unit.

Specifications of Model ESC-30V Shotcrete-Concrete Stress Cell

Range (MPa) | 1.0, 2.0, 3.5, 5.0, 10.0, 20.0, 30.0 specify |

Size (pressure pad) | 100 x 200 mm, 150 x 250 mm, 200 x 300 mm, 300 x 300 mm, specify |

Transducer Type | Vibrating Wire |

Accuracy | ± 0.5 % fs (standard) ± 0.1 % fs (available on request) With our EDI-51V vibrating wire indicator (non-linearity + hysteresis + repeatability) |

Temperature limit Operational Compensated | -20 to 80°C0 to 55°C |

Over Range Limit | 150 % of range |

Over Range Effect | ± 0.1% fsd up to 120% |

Thermistor | YSI 44005 or equivalent (3kOhms at 25°C) |

Features of Encardio Rite’s Pressure Cells:

Encardio Rite’s Models of Pressure Cells are one of the best in the market because they have the following features:

- The pressure cells are accurate, robust, and easy to install.

- They have long-term stability with high reliability.

- They have low volumetric displacement.

- The pressure cells are fluid-filled for high rigidity, accuracy, and fast response.

- The pressure cells are made up of stainless steel Thus, are corrosion-free and waterproof.

- You can read data remotely by online data loggers.

- They have high sensitivity and high-pressure range.

- A thermistor is available for temperature correction.

- Transmission of the signal as a frequency over long cable lengths.

- The vibrating wire sensor assures long-term stability and quick and easy readout.

- Pinch tube for inflation in concrete.

- Readily adaptable to data loggers.

This was all about the different types of pressure cells, their working principle, construction, specifications, and application areas.